|

1. CAST STEEL VALVES Service Features In the refineries, power plants, utilities and petrochemical/chemical process

industries, PK cast steel valves have been regarded as of great importance about

their excellent performance and reliability. Cast Steel Valves Production Range

| ||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

|

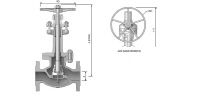

2. PARALLEL SLIDE GATE VALVE Features and benefits The parallel slide gate assembly consists of two interchangeable spring

loaded discs, a fully guided disc Springs are fitted between discs to provide initial sealing force only, and

do not maintain the sealing force. Discs are interchangeable which simplifies in-line maintenance and eliminates

the need to custom fit the Position seating eliminates stress and potential binding due to thermal

expansion of the stem. No additional torque required to achieve a positive seal once disc are in

position. Lower seating torque to reduce actuator size and cost. Hardfaced seating surfaces provide high cycle capability in very high

differential pressure services. By-pass valves are used to reduce the traversing differential pressure across

the valve seat. Equalizing devices are used to relieve the fluid trapped between the seat

forces, and to provide an outlet for the fluid displaced by the valve stem

traversing to the shut position. | ||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

|

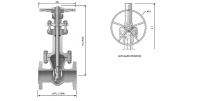

3.BELLOWS SEAL VALVES Operational Service Features 1. Useful life is ensured. 2. There is a grease nipple on all bellows seal gate valves under current

production to ensure correct The threads on stem in every kind of bellows seal valves should be kept clean

if possible and lubricated Valve Selection The globe valve should be selected for medium or high pressure steam, where

the isolation of vessels may be involved in safety problem. It is also used for

toxic or explosive media handling and in every case that a trouble may occur in

flow regulation. It should be noted that we have a specially designed valve of which dry

escape to gas or fluid is completely prevented. In the valve, conventional stem

packing is replaced with flexible metallic membrane where all possible leaking

paths through stem or body/bonnet joint are welded.

The bellows units applied to this valve were tested for life cycle to

destruction, resulting in satisfactory test results meeting the life time,

temperature, and pressure requirements of ASME B16.34. Low Fugitive Emission Valve Production Materials | ||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

|

|

상세설명

판매자에게 연락하기

업체명

0503-0000-0000

위 번호로 통화하여 제품정보를 확인하실 수 있습니다

견적 요청하기

로그인 후 이용가능합니다

견적 상세보기

로그인 후 이용가능합니다