상세설명

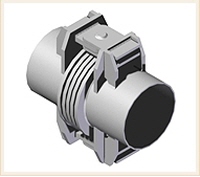

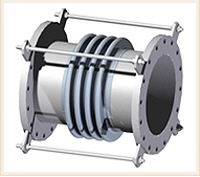

| Composition if a flexible hose A flexible hose is generally composed of metal hose, braids, and end fittings such as unions, flanges, nipples, and sockets. |

|

| 1) Metal Hose Made of stainless steel strips, metal hoses are highly elastic. Corrugated forming methods enhance metal hoses’ flex resistance and flexibility, reducing vibration at hoses by comprehensively processing stainless steel strips with the automatic forming machine and then heat-treating them in the automatic continuous bright suitable for general use under medium pressure and annular type, which is suitable for use under high pressure. 2) Braid When fluid pressure is under work inside the metal hose, the hose stretches length-wise. Should this occur, the brain restrains stretching and protects the metal hose from external shock. HKR’s hoses are manufactured with stainless steel wire up to 200A. When manufacturing a braid, we always consider working pressure and temperature. 3) End Fitting Flexible hoses are usually fixed by wilding end fittings to the ends of metal hose. The welding part is weak at corrosion than parent material because of heat stress. To address this problem, we manufacture flexible hoses to be as simple as possible to facilitate welding and assembly. |

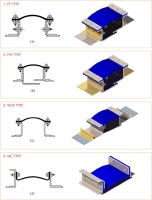

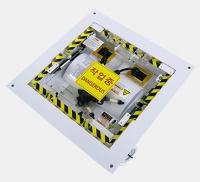

| CONNECTION TYPE |

|

|

Dia. | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | |||||

| 10A | PT 3/8 | |||||

| 15A | PT 1/2 | |||||

| 20A | PT 3/4 | |||||

| 25A | PT 1 | |||||

| 32A | PT1.1/4 | |||||

| 40A | PT1.1/2 | |||||

| 50A | PT 2 | |||||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | |||||

| 10A | PT 3/8 | |||||

| 15A | PT 1/2 | |||||

| 20A | PT 3/4 | |||||

| 25A | PT 1 | |||||

| 32A | PT1.1/4 | |||||

| 40A | PT1.1/2 | |||||

| 50A | PT 2 | |||||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||

|

|

Dia | T | D | I | H |

| 8A | PT 1/4 | 7 | 27 | 17 | ||

| 10A | PT 3/8 | 9 | 28 | 21 | ||

| 15A | PT 1/2 | 19 | 33 | 26 | ||

| 20A | PT 3/4 | 19 | 36 | 32 | ||

| 25A | PT 1 | 24 | 42 | 38 | ||

| 32A | PT1.1/4 | 32 | 44 | 46 | ||

| 40A | PT1.1/2 | 37 | 49 | 54 | ||

| 50A | PT 2 | 48 | 52 | 63 | ||