ABC65

CNC lathe for automatic turning to perfection

- The compact machine design with up to 3 simultaneously working tool carriers ensures high productivity

- Only 5.5 sqm footprint (without bar loader)

- Turret with two standard Y-axes

(Interpolation of X-, C- and H-axis) - Turret indexing as NC rotary axis for multiple tool assignments and chip-to-chip times of 0.4 seconds

- Dual function of the lower X/Z slide: turret and swivel counter spindle for rear end machining

- 8 tool stations for extensive rear end machining

- Workpieces are removed fast and gently by a CNC-controlled shuttle

- CNC-control with touch-screen operation:

18.5-inch wide-screen display with full multi-touch surface

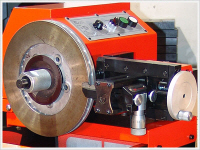

View into the work area

The symmetrical arrangement of the modules form the basis for a clearly structured work area with three tool carriers and two Y-axes (interpolated) both of which are usable on the main spindle with a clearance of 65 mm.

High axis acceleration, fast traversing and indexing speeds, Y-axes and a newly designed rear end machining unit open up new perspectives in terms of productivity and workpiece complexity for CNC automatic lathes.

The operation ? pioneering

Innovations in mind - The ABC65 is the first INDEX automatic lathe to have a 43.5 cm screen with full touch-sensitive surface (multi-touch) as standard equipment.

Because by means of touch technology, various selection and control switches on the machine control panel could be integrated directly into the screen ? which will considerably facilitate the operation of the machine while making it safer and more streamlined, without losing sight of familiar things. For example, the ABC65 is the first turning machine of INDEX that displays only those switches and buttons, depending on the situation, that actually apply to the current machine status.

Please find further informations of new innovative cnc control in Brochure of ABC65.

Technical Data

|

|

|

|

| |

|

Spindle clearance |

mm |

65 |

| |

|

Max. speed |

rpm |

6000 |

| |

|

Drive power at 100% ED |

kW |

25 |

| |

|

Torque at 100% ED |

Nm |

80 |

| |

|

Upper Tool Turret |

|

|

| |

|

Number of stations |

|

10 |

| |

|

Max. speed |

rpm |

12000 |

| |

|

Slide travel X / Z |

mm |

140 / 300 |

| |

|

Rapid traverse rate X / Z |

m/min |

30 / 50 |

| |

|

Chip-to-chip time |

s |

0.4 |

| |

| Lower Tool Turret | ||||

|

Number of stations |

9 | |||

| Max. speed | rpm | 12000 | ||

| Slide travel X / Z | mm | 140 / 300 | ||

| Rapid traverse rate X / Z | m/min | 30 / 50 | ||

|

Chip-to-chip time |

s | 0.4 | ||

| Counter Spindle | ||||

| Spindle clearance | mm | 52 | ||

| Max. speed | min-1 | 6000 | ||

| Drive power at 100% ED | kW | 5 | ||

| Torque at 100% ED | Nm | 10.5 | ||

| Rear End Machining Unit | ||||

|

Number of stations (live) |

|

8 (5) |

| |

|

Max. speed |

|

12000 |

| |

| Control | INDEX C200-4D (based on Siemens 840D sl) | |||

Subject to change without notice