상세설명

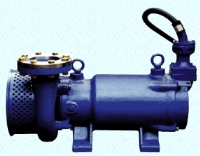

| Two Stage Liquid Ring Vacuum Pumps |

| The T Series liquid ring vacuum pumps were

created for the High Vacuum operation in the general, chemical,

petrochemical, foods, semi-conductor and power industries. These pumps with their integral two stage rotors are able to condense vapors that come off the process and to recover or dispose of them. |

|

| ||

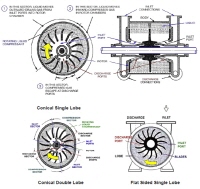

| Two Stage Conical Pump T7SD | Two Stage Conicail T5SM | ||

|

| ||

| Two Stage Flat Sided Pump | Two Stage Conical T12SM | ||

|

| ||||||||||||||

| Integrated Two Stage Design to Improve system

performance and efficiency Accepts single, double and cartridge mechanical seals to meet your process Pumps has V-Belt or flexible coupling drive to Numerous installation options Integral two stage rotor can attain high vacuum without additional components VACCOMP pumps has the Shrouded rotor blades to Strength and reliability VACCOMP pumps has Removable bearing bracket for Easier maintenance ISO, ANSI, DIN & KS connections available to Meets global requirements We offered in Hastelloy, Titanium, Duplex SS, Monel for corrosion resistance They are designed to operate at very low suction pressure level (less than 10 TORR) with low vapor pressure seal liquids. The Liquid Ring Pump Advantages. The Liquid ring vacuum Pumps and Compressors that use a rotating seal liquid in lieu of pistions, vanes or rotating lobes are the sensible choice as they provide you with benefits not possible with other alternatives : + No Metal to Metal Contact + No Internal Lubrication Required + Only One Moving Part - No Vanes, No Valves, No Timing Gears or Chains + Minimal Temperature Differential Between Inlet and Discharge of the Pump + Ability to Handle Large Quantities of Process Carryover Liquids or Solids |

|

| Main Applications. | Select a Vacuum Pump. | Standard Components. |

| + Autoclaves & Deaerating + Chucking & Drying + Condenser Exhauster & Evaporating + Chlorine Compression + Gas Stripping & Filtering + Hydrocarbon Recovery + Laboratory Central Vacuum System |

+ Gas carries solids & Gas is corrosive + Vapor is to be reclaimed & Liquid carry over + Cut pollution control costs + When High Vacuum Needed + Idea for energy Cost Saving + Pump Priming & Water Treatment |

+ Vacuum Pump or Compressor + Single or Double Mechanical Seal + Motor, Direct or V-Blet Drive and Base + Separator Drain valve for Compressor + Heat Exchanger for Re-circulation Seal + Solvent Recovery |