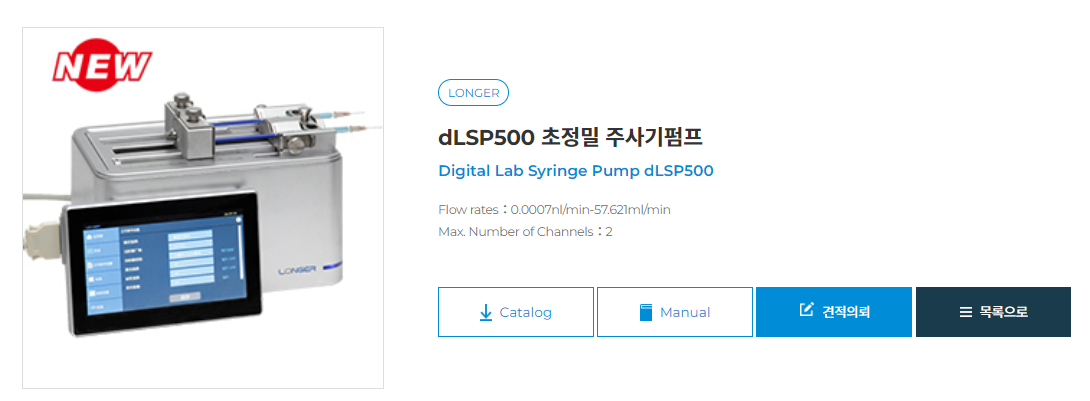

※개요

•이더넷 및 무선(Wifi/블루투스) 통신, 전용 PC 소프트웨어 및 Android 앱, 원격 제어 및 모니터링 허용

•지능형 진단 및 음성 알림을 통해 작업 진행 상황 및 펌프 상태를 실시간으로 알 수 있습니다.

•EMC 기능이 탑재되어 높은정밀도 및 안정적인 유체 이송을 필요로 하는 미세 유체[Microfluidic] 및 전기 방사 응용 분야[Electrospinning]에 적합합니다.

•직관적인 그래픽 인터페이스를 갖춘 7인치 풀 터치 스크린

•사용자 정의 매개변수를 빠르게 구성할 수 있으며 매개변수 방법을 저장하고 쉽게 불러올 수 있습니다.

•안전 관리를 위한 사용자 접근 제어 및 로그 기록. 전자 서명 기능으로 Pro 펌프는 FDA(21CFR Part 11) 요구 사항을 충족할 수 있습니다.

※특징

•7-inch high-resolution touchscreen, Easy to Use

•Ethernet and wireless (Wifi/bluetooth) communication, and monitoring via PC, tablet, or smart phone

•Modular programming based on the workflow can automatically complete the switching of various working status according to the user-defined program

•Multi-pump mode of operations are easy to run and control through the various interfaces

•The buzzer, indicator light, text, voice reminder and other alerts support the users through the operation process

•Meet the requirement of 21CFR Part 11 to ensure the validity and reliability of electronic data

•Intelligent diagnosis and maintenance prompt provide quarantee for safe operation

※Application

•Electrospinning

•Microfluidics/ Microfluidic Chips

•Animal experiment

•Toxicology studies

•Capillary Electrophoresis

•Drug Discovery

•Cell injections

•Microcapsule

•Catalyzer

•Neuroscience

•Organic Synthesis

•Nutrition Science

※규격

|

ProductModel(Product Code) |

dLSP510 dLSP520 |

dLSP510Pro dLSP520Pro |

|

|---|---|---|---|

|

Syringe |

SyringeID (mm) |

Referenceflow rate (nL/min - mL/min) |

|

|

0.5ul |

0.1 |

0.0007-0.0014 |

0.0003-0.0007 |

|

5ul |

0.35 |

0.008-0.017 |

0.004-0.008 |

|

10ul |

0.5 |

0.016-0.035 |

0.008-0.017 |

|

25ul |

0.8 |

0.042-0.090 |

0.020-0.043 |

|

50ul |

1.1 |

0.079-0.171 |

0.038-0.082 |

|

100ul |

1.6 |

0.167-0.362 |

0.080-0.174 |

|

500ul |

3.25 |

0.691-1.493 |

0.332-0.717 |

|

1ml |

4.72 |

1.458-3.150 |

0.700-1.512 |

|

2ml |

9 |

5.299-11.451 |

2.545-5.497 |

|

5ml |

13.1 |

11.227-24.261 |

5.391-11.645 |

|

10ml |

16.6 |

18.028-38.956 |

8.657-18.699 |

|

20ml |

19 |

23.618-51.035 |

11.341-24.497 |

|

30ml |

23 |

34.609-74.786 |

16.619-35.897 |

|

60ml (510 series) |

29.14 |

55.554-120.044 |

26.677-57.621 |

※주문정보

|

|

dLSP 510 |

dLSP 520 |

dLSP 510 Pro |

dLSP 520 Pro |

|---|---|---|---|---|

|

Work mode |

Infusion only, withdrawalonly, infusion/withdrawal, withdrawal/infusion, auto repeated, programming(on delicated PC software) |

|||

|

Number of channel |

1 |

2 |

1 |

2 |

|

Pusher advance per microstep |

0.03255um/ustep |

0.015625um/ustep |

||

|

Linear speed |

0.0833um/min-180mm/min |

0.04um/min-86.4mm/min |

||

|

Step speed |

23.4375 sec/ustep-10.85usec/ustep |

|||

|

Linear travel accuracy (Rated) |

±0.5% |

±0.35% |

||

|

Linear travel CV(Rated) |

±0.05% |

|||

|

Linear force (Rated) |

40lbs/18kg @ 100% force selection |

|||

|

Motor and drive |

1.8˚ step motor with 1/64 microstepping |

|||

|

Syringe |

0.5uL-60mL |

0.5uL-30mL |

0.5uL-60mL |

0.5uL-30mL |

|

User-defined syringe |

Travel≤108mm, OD≤31.5mm |

Travel≤108mm, OD≤26mm |

Travel≤108mm, OD≤31.5mm |

Travel≤108mm, OD≤26mm |

|

Display |

7Inch, 1024 x 600, IPS HD LCD |

|||

|

Language |

Chinese or Englisht, set as needed |

|||

|

Control mode |

Touch screen control, dedicated PC or AndroidApp control, footswitch control, RS485 communication control |

|||

|

Interface |

RS485(optional), USB-B, USB-A, Wifi, Bluetooth,Ethernet, Footswitch |

|||

|

Wireless connetivity(optional) |

Wifi, Bluetooth |

|||

|

Programming function |

Parameter configured based on work flow : constant,ramp, loop, delay, repeat, I/O output trigger, I/O event input trigger,touch |

|||

|

Calibration |

Improve flow rate/ dispensing volume precisionand accuracy |

|||

|

Parameter method |

Parameter methods can be stored and easily realled |

|||

|

Real time clock |

Date and time can be set |

|||

|

Audible alarm |

For keypad clicks, end of run, near end of run,power on, motor stall, calibration reminder, etc. |

|||

|

Voice remider |

N/A |

For working progress, alarm, diagnosis |

||

|

Intelligent diagnosis |

N/A |

For presence or syringes, syringe leakage |

||

|

Screen lock |

To prevent misoperation |

|||

|

User access control |

Three levels of users accesses (administator,developer, operator), in line with safety management requirement(21CFRPart 11) |

|||

|

Predictive maintenance |

Real-time monitoring of pump running status prividinginformaiton such as alarms, regular maintenance, predictive maintenance |

|||

|

Log record |

Record the complete operation history of the pump,and can be exported directly |

|||

|

Electronic signature and audit trail |

N/A |

Meet the requirement of 21CFR Part 11 (on dedicatedPC software) |

||

|

Support 3Q(IQ/OQ/PQ) |

Meet GMP requirement |

|||

|

EMC |

CE (TUV) certified |

|||

|

Dimension |

Drive unit : 260mm*185mm*180mm, Controller : 190mm*123mm*33mm |

|||

|

Power supply |

AC 100V-240V/30W 50/60Hz |

AC 100V-240V/20W 50/60Hz |

||

|

Operating condition |

Temperature : 5˚C-40˚C, Relative humidity<85% |

|||

|

IP rating |

IP31 |

|||

|

Weight |

Drive unit : 3.49kg, Controller : 0.37kg |

|||