소형 탁상용 연마기 (다용도 가공기)

다기능 소형 탁상 가공기

Hot selling desktop milling machine, manual scale slotter, mini slotting machine price

Feature:

1.This manual milling machine is small and exquisite, also with beautiful appearance.

2.Good accuracy and stability, easy to operate.

3.Widely used in non-ferrous metals and plastics, plexiglass, wood sawing, milling, engraving, milling and other milling, the above cutting can be done in any position.

4.Spindle arbor default 22MM, can be customized 16MM.

Specification:

M1514 desktop manual grooving machine

Table size | 335x130mm |

Horizontal travel | 110mm |

Vertical travel | 180mm |

Lifting travel | 180mm |

Table rotation | -45 degree |

Power | 750W |

Spindle speed series | 3 level |

Machine size | 650x600x660mm |

Weight | 93kg |

Spindle spee | 610/1400/2700 r/min |

T slot width | 12mm |

T-slot pitch | 68mm |

중국 선반/밀링기/연마기

해외직구 구입관련 길잡이 안내

덕주코리아 - 중국 공작기계 취급전문( 30여년 취급경험)

덕주코리아와 협의를 통해 좋은 구매 결과를 얻으시기 바랍니다

이왕이면 좀 더 우수한 메이커 것을 선정

사후관리도 원활한 것으로

제대로 필요한 부품 사전에 기계구매시 동시 확보

중고 가치가 계속 높게 유지되는 것으로

이미 성능과 품질이 정평이 나 있는 것으로

심층 파악

선반 주축경이 큰 대주축경 선반

밀링 소형 밀링기 /1.5호기 밀링/양두밀링

연마기소형 평면연마기/칼날연마기/공구 연마기

래디얼 40*1300/50*1600/63*2000

와이어컷팅기/레이져가공기

프레스/절곡기 /파이프 밴딩기

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot selling desktop milling machine, manual scale slotter, mini slotting machine price

Feature:

1.This manual milling machine is small and exquisite, also with beautiful appearance.

2.Good accuracy and stability, easy to operate.

3.Widely used in non-ferrous metals and plastics, plexiglass, wood sawing, milling, engraving, milling and other milling, the above cutting can be done in any position.

4.Spindle arbor default 22MM, can be customized 16MM.

Specification:

M1514 desktop manual grooving machine

Table size | 335x130mm |

Horizontal travel | 110mm |

Vertical travel | 180mm |

Lifting travel | 180mm |

Table rotation | -45 degree |

Power | 750W |

Spindle speed series | 3 level |

Machine size | 650x600x660mm |

Weight | 93kg |

Spindle spee | 610/1400/2700 r/min |

T slot width | 12mm |

T-slot pitch | 68mm |

3.연마기

가. 미국OEM PSG-206

Main features of Mini tool surface grinding machine MJ7115 :

1)Integrated grinding head of high quality, high rigidity and accuracy.

2)Small size, light weight, easy operation & maintenance.3

3)Centralized lubrication for oil pump.

Specification and data of Mini tool surface grinding machine MJ7115

Specification | Metric | Inch(“) |

Longitudinal stroke | 340mm | 14 |

Cross stroke | 170mm | 7 |

Vertical stroke | 210mm | 8 |

Table size(W*L) | 152mm×304mm | 6×12 |

Width of T-slot | 1-12mm | 1-0.47 |

Cross feed per graduation | 0.02mm | 0.001 |

Cross feed per round | 2.54mm | 0.1 |

Vertical feed per graduation | 0.025mm | 0.001 |

Vertical feed per round | 1.25mm | 0.05 |

Size of grinding wheel | 180mm×32mm×13mm | |

Motor power | 0.55kw | |

Roughness | 1.6μm | |

N.W. / G.W. of machine | 210/258kg | |

N.W. / G.W. of stand | 30/54kg | |

Overal dimensions of machine | 930×780×730mm | |

Case dimensions of machine | 930×780×1480mm | |

Case dimensions of stand | 720×550×550mm | |

The detailed parts of Mini tool surface grinding machine MJ7115

The package and workshop of Mini tool surface grinding machine MJ7115

Regarding the grinder machine MJ7115, please check my reply as follows: 1、The machine change from lead screw model to ball guid model did not change the axis. Difference of between lead screw model and ball guid model just is guide different. please check the pictures show as follows:  Lead screw model Lead screw model  ball guid model ball guid model 2、stand : 3、 permanent magnetic chuck , size : 150x300mm  .jpg?inlineContentType=application/octet-stream&inlineFileSize=102473&inlineId=MjoxLjU6MjQyNjY0MToxNDAyMjY6YXBwbGljYXRpb24vb2N0ZXQtc3RyZWFtOmJhc2U2NDpWeGI2LU9hWkJsSlBBZm9sMzE1b2x3) 4、Precision flat vise : precision flat vise for MJ7115.jpg?inlineContentType=application/octet-stream&inlineFileSize=178454&inlineId=MjoxLjY6MjU2NzI5NjoyNDQyMDA6YXBwbGljYXRpb24vb2N0ZXQtc3RyZWFtOmJhc2U2NDpWeGI2LU9hWkJsSlBBZm9sMzE1b2x3) |

X1415B 다기능 소형 탁상 가공기

Hot selling desktop milling machine, manual scale slotter, mini slotting machine price

Feature:

1.This manual milling machine is small and exquisite, also with beautiful appearance.

2.Good accuracy and stability, easy to operate.

3.Widely used in non-ferrous metals and plastics, plexiglass, wood sawing, milling, engraving, milling and other milling, the above cutting can be done in any position.

4.Spindle arbor default 22MM, can be customized 16MM.

Specification:

M1514 desktop manual grooving machine

Table size | 335x130mm |

Horizontal travel | 110mm |

Vertical travel | 180mm |

Lifting travel | 180mm |

Table rotation | -45 degree |

Power | 750W |

Spindle speed series | 3 level |

Machine size | 650x600x660mm |

Weight | 93kg |

Spindle spee | 610/1400/2700 r/min |

T slot width | 12mm |

T-slot pitch | 68mm |

중국 선반/밀링기/연마기

해외직구 구입관련 길잡이 안내

덕주코리아 - 중국 공작기계 취급전문( 30여년 취급경험)

덕주코리아와 협의를 통해 좋은 구매 결과를 얻으시기 바랍니다

이왕이면 좀 더 우수한 메이커 것을 선정

사후관리도 원활한 것으로

제대로 필요한 부품 사전에 기계구매시 동시 확보

중고 가치가 계속 높게 유지되는 것으로

이미 성능과 품질이 정평이 나 있는 것으로

심층 파악

선반 주축경이 큰 대주축경 선반

밀링 소형 밀링기 /1.5호기 밀링/양두밀링

연마기소형 평면연마기/칼날연마기/공구 연마기

래디얼 40*1300/50*1600/63*2000

와이어컷팅기/레이져가공기

프레스/절곡기 /파이프 밴딩기

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot selling desktop milling machine, manual scale slotter, mini slotting machine price

Feature:

1.This manual milling machine is small and exquisite, also with beautiful appearance.

2.Good accuracy and stability, easy to operate.

3.Widely used in non-ferrous metals and plastics, plexiglass, wood sawing, milling, engraving, milling and other milling, the above cutting can be done in any position.

4.Spindle arbor default 22MM, can be customized 16MM.

Specification:

M1514 desktop manual grooving machine

Table size | 335x130mm |

Horizontal travel | 110mm |

Vertical travel | 180mm |

Lifting travel | 180mm |

Table rotation | -45 degree |

Power | 750W |

Spindle speed series | 3 level |

Machine size | 650x600x660mm |

Weight | 93kg |

Spindle spee | 610/1400/2700 r/min |

T slot width | 12mm |

T-slot pitch | 68mm |

3.연마기

가. 미국OEM PSG-206

Main features of Mini tool surface grinding machine MJ7115 :

1)Integrated grinding head of high quality, high rigidity and accuracy.

2)Small size, light weight, easy operation & maintenance.3

3)Centralized lubrication for oil pump.

Specification and data of Mini tool surface grinding machine MJ7115

Specification | Metric | Inch(“) |

Longitudinal stroke | 340mm | 14 |

Cross stroke | 170mm | 7 |

Vertical stroke | 210mm | 8 |

Table size(W*L) | 152mm×304mm | 6×12 |

Width of T-slot | 1-12mm | 1-0.47 |

Cross feed per graduation | 0.02mm | 0.001 |

Cross feed per round | 2.54mm | 0.1 |

Vertical feed per graduation | 0.025mm | 0.001 |

Vertical feed per round | 1.25mm | 0.05 |

Size of grinding wheel | 180mm×32mm×13mm | |

Motor power | 0.55kw | |

Roughness | 1.6μm | |

N.W. / G.W. of machine | 210/258kg | |

N.W. / G.W. of stand | 30/54kg | |

Overal dimensions of machine | 930×780×730mm | |

Case dimensions of machine | 930×780×1480mm | |

Case dimensions of stand | 720×550×550mm | |

The detailed parts of Mini tool surface grinding machine MJ7115

The package and workshop of Mini tool surface grinding machine MJ7115

Regarding the grinder machine MJ7115, please check my reply as follows: 1、The machine change from lead screw model to ball guid model did not change the axis. Difference of between lead screw model and ball guid model just is guide different. please check the pictures show as follows:  Lead screw model Lead screw model  ball guid model ball guid model 2、stand : 3、 permanent magnetic chuck , size : 150x300mm  .jpg?inlineContentType=application/octet-stream&inlineFileSize=102473&inlineId=MjoxLjU6MjQyNjY0MToxNDAyMjY6YXBwbGljYXRpb24vb2N0ZXQtc3RyZWFtOmJhc2U2NDpWeGI2LU9hWkJsSlBBZm9sMzE1b2x3) 4、Precision flat vise : precision flat vise for MJ7115.jpg?inlineContentType=application/octet-stream&inlineFileSize=178454&inlineId=MjoxLjY6MjU2NzI5NjoyNDQyMDA6YXBwbGljYXRpb24vb2N0ZXQtc3RyZWFtOmJhc2U2NDpWeGI2LU9hWkJsSlBBZm9sMzE1b2x3) |

X1415B 다기능 소형 탁상 가공기

Hot selling desktop milling machine, manual scale slotter, mini slotting machine price

Feature:

1.This manual milling machine is small and exquisite, also with beautiful appearance.

2.Good accuracy and stability, easy to operate.

3.Widely used in non-ferrous metals and plastics, plexiglass, wood sawing, milling, engraving, milling and other milling, the above cutting can be done in any position.

4.Spindle arbor default 22MM, can be customized 16MM.

Specification:

M1514 desktop manual grooving machine

Table size | 335x130mm |

Horizontal travel | 110mm |

Vertical travel | 180mm |

Lifting travel | 180mm |

Table rotation | -45 degree |

Power | 750W |

Spindle speed series | 3 level |

Machine size | 650x600x660mm |

Weight | 93kg |

Spindle spee | 610/1400/2700 r/min |

T slot width | 12mm |

T-slot pitch | 68mm |

DAESANG MACHINE DEZHOU KOREA CORP. TEL:82-2-2068-3312

M:010-2845-4417 E-MAIL :sksea99@daum.net

CHINA DEZHOU PRECION www.dzjc.com GRINDER www.sunnyfreeport.com

DAESANG MACHINE DEZHOU KOREA CORP. TEL:82-2-2068-3312

M:010-2845-4417 E-MAIL :sksea99@daum.net

CHINA DEZHOU PRECION www.dzjc.com GRINDER www.sunnyfreeport.com

DAESANG MACHINE DEZHOU KOREA CORP. TEL:82-2-2068-3312

M:010-2845-4417 E-MAIL :sksea99@daum.net

CHINA DEZHOU PRECION www.dzjc.com GRINDER www.sunnyfreeport.com

소형 공작기계 콤비 안내 -덕주코리아 문의 010 2845 4417

해외직구식 구매로 가격부담 없음

특별염가로 디지탈(DRO 장착등)/추가 옵션 품목첨가 수입구매

시운전/사후관리 염가써비스로 장기적 안심 장비사용

소형선반 280*500/320*750/360*900/400*1000

(* 소형선반 대주축경 특별 스펙 취급전문)

소형밀링 테이블 110*480/240*820/254*1270 (1.5호기 밀링)

(*1.5호기 밀링기 다양한 스펙 구비 상담 전문)

소형연마기 150*300/200*400/250* 500

(*초소형 연마기 평면/원통/칼날/공구 연마기 취급전문)

소형 레디얼기 40*1300/50*1600/63*2000

(* 레디얼기의 변신 특수 스펙 상담)

소형 와이어 컷 DK7735 430* 790

(* 특수 스펙/특수규격 상담전문)

소형 테핑기 M2-M16

1. 소형선반 대표모델 자료 참조

1. Precision ground and hardened bed ways.

2.The spindle is supported with precision roller bearings.

3.Headstock gears are made of high quality steel,ground and hardend.

4.Easy operating gear box has various feeds and thread cutting function.

5.Spindle speed range 90-1800rpm.

6.It can cut diametral threads and module threads.

Technical Specifications

|

Product Image

2. The spindle is supported with precision roller bearings.

3. Headstock gears are made of high quality steel, ground and hardened.

4. Easy operating speed change levers.

5. Spindle speed range 60-1600rpm.

6. Two different lengths of bed are available.

7. With or without cabinet according to requirement.

· Dead center

· Change gears set

· Splash guard

· Oil gun

· Tool box and tools

· Machine stand

· Face plate

· Steady rest

· Follow rest

· Live center· Toolpost cover

· Chuck guard

· Leadscrew guard

2.밀링기

1. ZX 16 초소형

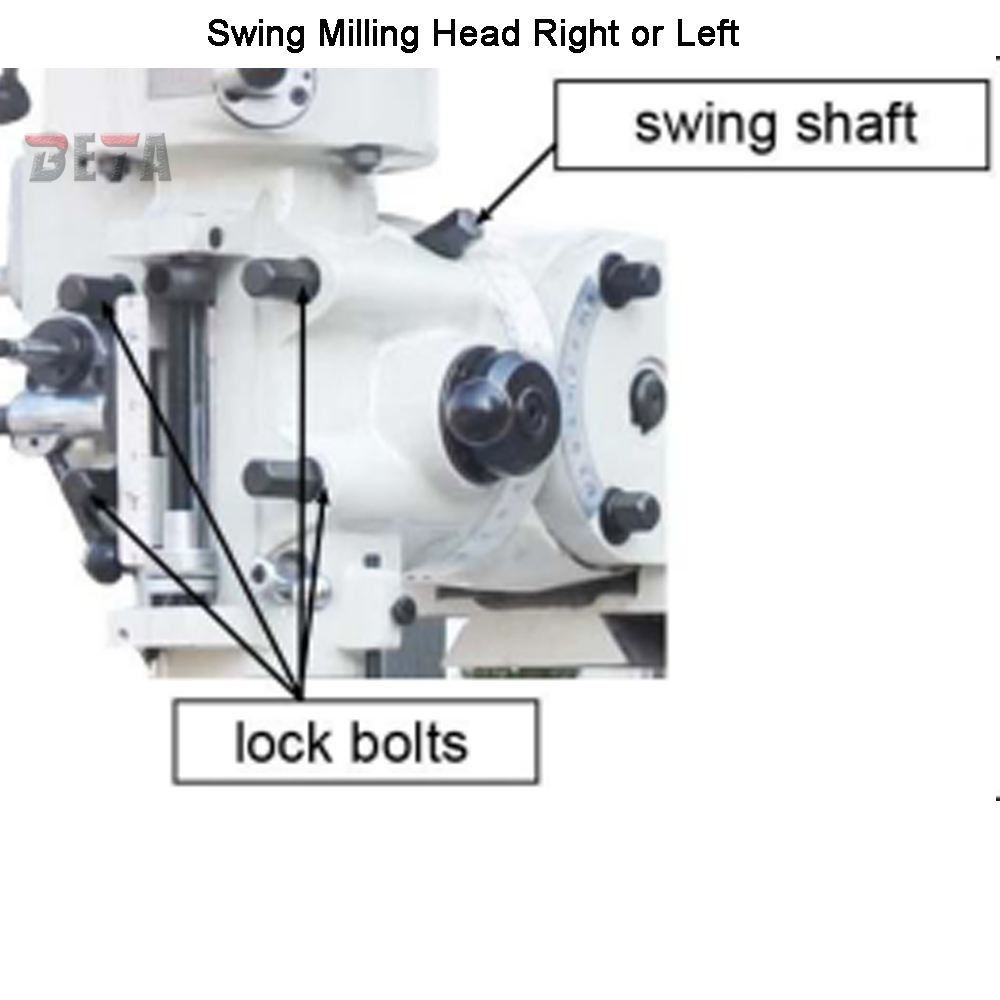

This highly precise drilling and milling machine is ideal perhaps for a smaller or more compact workshop, or simply where space is an issue. Bench mountable,

Has a head that tilts 45°left and right (from vertical), is robustly constructed from steel.

It also comes with all the necessary tools and accessories to successfully use and maintain it.

There s a fine feed for milling and a coarse feed for drilling, plus an easy-to-read dial with .0001" increments so you get the right setting.

| Maximum drilling diameter | 13mm |

| Maximum face milling capacity | 30mm |

| End Milling Capacity | 16mm |

| Workbench size | 485×110mm |

| T-slot size | 12mm |

| X-axis travel | 300mm |

| Y-axis travel | 130mm |

| Z-axis travel | 180mm |

| Spindle taper | MT3/R8 |

| Spindle speed/Grade | 50-2500rpm/variable |

| Motor | 600w |

| N.W./G.W. | 62/80kg |

| Packing size | 550×550×735mm |

2. small milling cnc XK7113C CTMACH 1005

Applications:

- Suitable for home workshop DIY handicrafts, maintenance of cars and motorcycles in the workshop, teaching demonstrations used by schools, science and technology centers and research institutes, small and medium-sized factory small batch parts cut machining and repair.

- Small size, strong rigidity and high precision. Durable and easy to maintain

Small wasp CNC Machine Tool(CTMACH-1005)

Technical Specifications

Workbench | |

Size(length *width) | 400*140mm |

T-shaped groove(groove width*number*spacing) | 12*3*24mm |

Maximum load | 40KG |

Workbench trip | |

X | 220mm |

Y | 120mm |

Z | 200mm |

Maximum distance from the end face of the spindle to the table | 280mm |

Spindle center to colum surface distance | 190mm |

Spindle | |

Spindle taper | ER20 |

Maximum spindle speed | 3000r/min |

Motor and speed | |

| Spindle motor rated power | 400w |

| Rated torque | 1.4N.M |

| X Y Z axis Motor torque | XY:2.5N.M Z:3.2N.M |

| Maximum feed rate | 2500 |

Positioning progress | - 0.02mm |

Repeat positioning progress | - 0.015mm |

Packing box | |

Size (L*W*H) | 600*760*790mm |

Net weight/gross weight | 95/115kg |

Product Display

Primary Competitive Advantages:

- Country of Origin

- Distributorships Offered

- Experienced Staff

- Guarantee/Warranty

- Product Features

- Product Performance

- Prompt Delivery

- Small Orders Accepted

- If you can't find your details,Please contact with me,then We can provide professional sevice.

- It would be better send us your drawing or CAD pictures for specialized design,then we

3. 테이블 200*800

3. 소형연마기

덕주코리아 제공 중국 소형 연마기 자료 안내

1.초소형 간이 경제형 탁상 연마기 모델 X1415B 테이블 130*330

*초소형 가공물 기초연마에 적합 정밀도 0.08MM

*동기기 장점:타용도로 다가공기능 활용가능

2.소형 탁상 정밀연마기 (볼 가이드레일)정밀도 0.02MM 테이블 150*300

*미국 OEM 모델 30년 모델 PSG 206

*장점 : 매우 컴팩트구조로 정밀연마가공

3. 소형 기본 연마기 테이블 200*400 모델 M818A

* 영구자석척이 표준이나 전기자석척 장착가능

* 가격부담이 안됨

4. 성형연마기 기본 규격 250*500

동규격으로는 매우 다양한 등급이 있음

가. 완전 수동 B급

나. X 유압구동 YZ 전기구동

다. 반자동 PLC 모델

상기 연마기 관련 자료 1/2/3 하기 상세자료 검토 바랍니다

* 4번 상세자료사항은 기본상담후 상세정밀자료 제공합니다

단 기본자료 유첨하니 참고 바랍니다

1.X1415B 다기능 소형 탁상 가공기

Hot selling desktop milling machine, manual scale slotter, mini slotting machine price

Feature:

1.This manual milling machine is small and exquisite, also with beautiful appearance.

2.Good accuracy and stability, easy to operate.

3.Widely used in non-ferrous metals and plastics, plexiglass, wood sawing, milling, engraving, milling and other milling, the above cutting can be done in any position.

4.Spindle arbor default 22MM, can be customized 16MM.

Specification:

M1514 desktop manual grooving machine

Table size | 335x130mm |

Horizontal travel | 110mm |

Vertical travel | 180mm |

Lifting travel | 180mm |

Table rotation | -45 degree |

Power | 750W |

Spindle speed series | 3 level |

Machine size | 650x600x660mm |

Weight | 93kg |

Spindle spee | 610/1400/2700 r/min |

T slot width | 12mm |

T-slot pitch | 68mm |

2. PSG 206(미국 OEM 모델)

Send your message to this supplier

4. 250*500 성형연마기 기본 규격 모델

4-1 완전수동 경제형

4-2 X 유압구동식

4-3 PLC CONTROL 형

4-3

DAESANG MACHINE DEZHOU KOREA CORP. TEL:82-2-2068-3312

M:010-2845-4417 E-MAIL :sksea99@daum.net

CHINA DEZHOU PRECION www.dzjc.com GRINDER www.sunnyfreeport.com

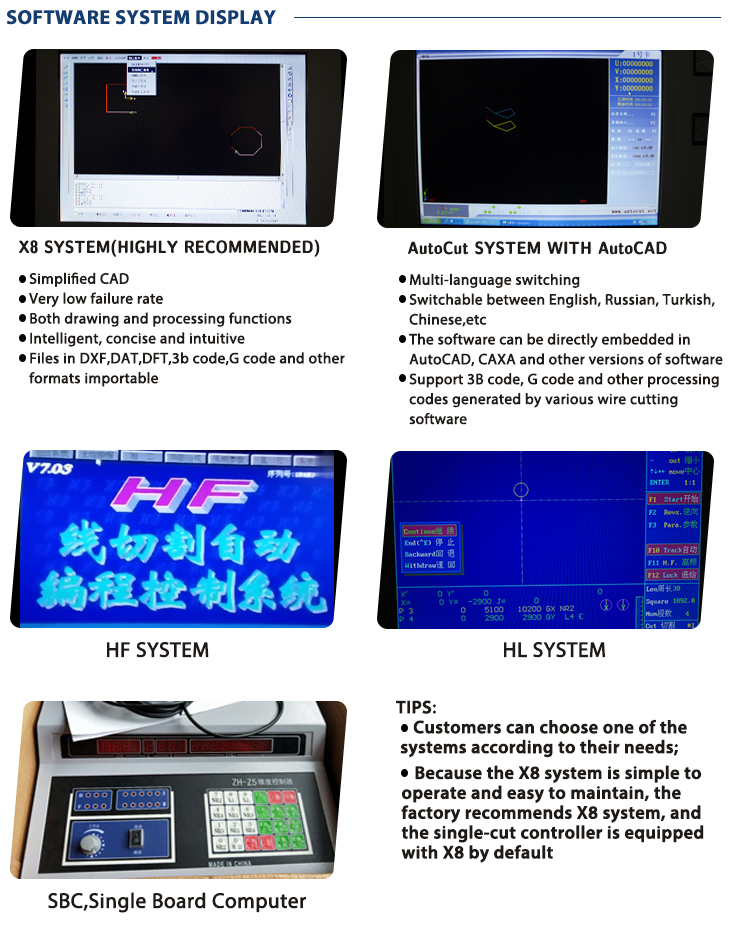

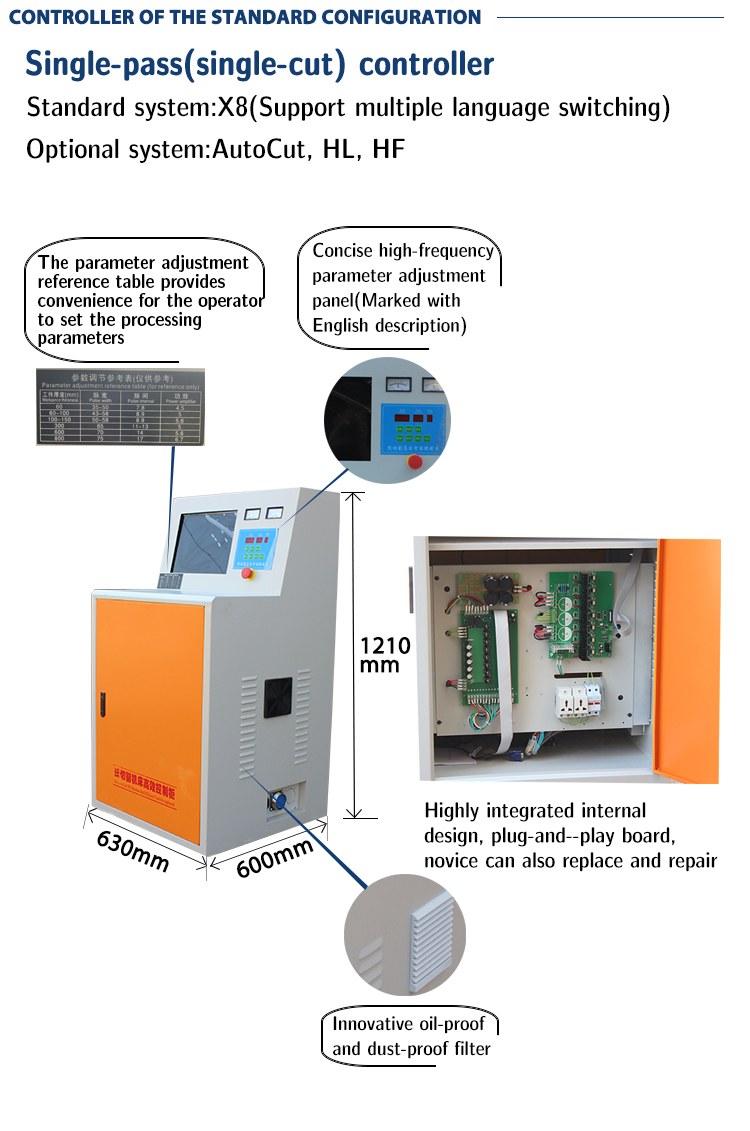

1. TAIZHOU TERUI

1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional)

2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm)

3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut);

4.Molybdenum wire diameter:0.1-0.2mm;

5.Max. cutting speed≥120mm^2/min;

6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW;

7.Working fluid:Water-based emulsion.

0.18mm molybdenum edm wire

0.18mm molybdenum edm wire

Feature of molybdenum wire for cnc edm cutting

• High melting point, Low density and Thermal coefficients

• Good thermal conductivity properties and Resistance of high-temperature

• High tensile strength and Low elongation

• Good stability and High precision of cutting

• High speed and Long stable time of processing

• Long lifetime and Non-poisonous

Application of molybdenum wire for cnc edm cutting

• Electric light source, Electrode

• Heating elements, High-temperature components

• Wire-electrode cutting

• Spraying for auto parts

Automatic servo motor electric tapping machine with touch screen

We are OEM factory for manufacturing high quality tapping machine.Now let me tell you the application of tapping machine. Tapping machine is widely used for coarse and fine teeth, non-standard tooth pitches and reverse-tightening connection threads, driving connection threads and pipe threads for various small and large steel parts.

Detailed Parametersof Tapping machine:

| Model | Tap Size | Voltage | Speed | Max Radius | Way to Work | Chunk Choice |

| M3-M12 | M3-M12 | 220v | 312r/min | 1000mm | Universal head | ISO/DIN/JIS M3-M12 collet |

| M3-M16 | M3-M16 | 220v | 312r/min | 1000mm | Universal head | ISO/DIN/JIS M3-M16 collet |

| M6-M24 | M6-M24 | 220v | 200r/min | 1200mm | Universal head | ISO/DIN/JIS M6-M24 collet |

| M6-M30 | M6-M30 | 220v | 150r/min | 1200mm | Universal head | ISO/DIN/JIS M6-M30 collet |

| M6-M36 | M6-M36 | 220v | 150r/min | 1200mm | Universal head | ISO/DIN/JIS M6-M36 collet |

Three Collets of tapping machine for you choice, you can as your demands, and then let us know is ok.

Small hole high speed tapping machine, a unique leading-edge technology, to ensure that the tap will not be broken.

1. Used in military precision instrumentation, mold and other industries thread processing;

2. Solve problems that tap easily broken and be jammed during processing micro & deep hole threads;

3. Adopt U.S. dual-core chip CNC system;

4. Can set the depth of the hole and different materials;

5. Fast tracking, security tapping; Can dynamic display the real-time data;

6. Can record the depth, number of turns, screw pitch and other data of processed thread;

7. Can be used for analyzing the data of laboratory;

8. Can replace the desktop machine.

Other type of tapping machine for your choice, here i recommend our newest made machine, which can be automatic lubrication and air blowing:

Details of electric tapping machine:

Packaging Details | Standard export box, container or can be adjusted according to your demands |

Delivery Details | Within 5-7 days after payment received |

M3-M16 M6-M24 Servo Vertical Tapping Machine,Electric Drilling And Tapping Machine

The product is suitable for work piece material:

Electric tapping machine can be easy to tap in lead, copper, steel, cast iron, pig iron, 45 steel, die steel, metal material and other metal materials.

Applicable to all machinery manufacturing industry, machine tools, mold machinery, printing machinery, packaging machinery manufacturing plants, construction machinery, rolling stock, aircraft engines, plastic machinery and general machinery and other industries

Model | M6-M24 |

Working pressure | 220V |

Motor power | 1200W |

Working current | 50Hz |

Tapping capacity | M6-M24 |

Working type | Verticle/Universal |

Working radius | 1200mm |

Control panel | Touch-screen/Button type |

Max. speed | 0-200rpm |

Custom speed | 600/1000R |

Chuck (8Pcs) | 6-8/10/12/14/16/18-20/22/24 |

Weight | 48kg |

Optional accessories | 1. 600kg magnetic base 2. 500*800/600*900 working table |

DAESANG MACHINE DEZHOU KOREA CORP. TEL:82-2-2068-3312

M:010-2845-4417 E-MAIL :sksea99@daum.net

CHINA DEZHOU PRECION www.dzjc.com GRINDER www.sunnyfreeport.com

덕주코리아 중국 공작기계 취급전문 상세안내

*중국 공작기계 취급30년이상(대만공작기계 병행취급 수십년)의 경험으로

공작기계나 산업기계 구매시 중국 기계 구입 조언 컨설팅 포함 실제 구매진행 컨설팅 제공합니다

과연

중국 덕주기상창(선반과 디프홀 가공기 선도기업) 한국총판및 아프터써비스 총괄 www.dzjc.com

중국 웨이다 기상창(밀링과 레디얼드릴링기 선도기업) www.weida-mc.com

중국 톱텍 레이져 용접기 서울지역 총괄 www.topteklaser.com (레이져 세척기/마킹기/컷팅기 일체)

중국 칼날연마기 www.hishengyang.com(모든 칼날연마기 제조 )

중국 1.5호기 밀링 www.huadongcnc.com (소형 연마기 포함)

중국 초소형 탁상연마기 www.jinxingjichuang.com (각종 소형 탁상 선반/밀링기포함)

중국 와이어 컷팅기 (www.teruimachine.com ) 몰리브덴 와이어 컷/흑연 와이어 컷

중국 프레스/절곡기/롤밴딩기 (www.ysdcnc.com)

중국 C형 고속프레스 www.goanwin.com

중국 알류미늄 컷팅기 www.sdmmcnc.com

중국 사출기 www.haitai-machine.com

중국 원통/롤연마기 www.smtw.com 소형 원통연마기 www.tbrkj.com TEBER CNC CYLINDRICAL GRINDER

대만 써니연마기 www.sunnyfreeport.com (대만 평면연마기 최고급 초정밀/초대형 연마기 선도기업)

대만 산이글 특수전용기및 특수기계 www. saneagle.com.tw 모든 대만 공작기계종합취급

수직선반 경제형 www.dlhaidi.cn 고급형 www.fulltontech.com

양두밀링 www.amitmc.com JIAZHAO