와이어컷 가공기 문의 덕주코리아

문의 010 2845 4417

와이어 컷 가공기 ---> 몰리브덴 와이어컷 가공기

한국시장에도 몰리브덴 와이어컷 가공기가 지속적으로 판매공급되고 있읍니다

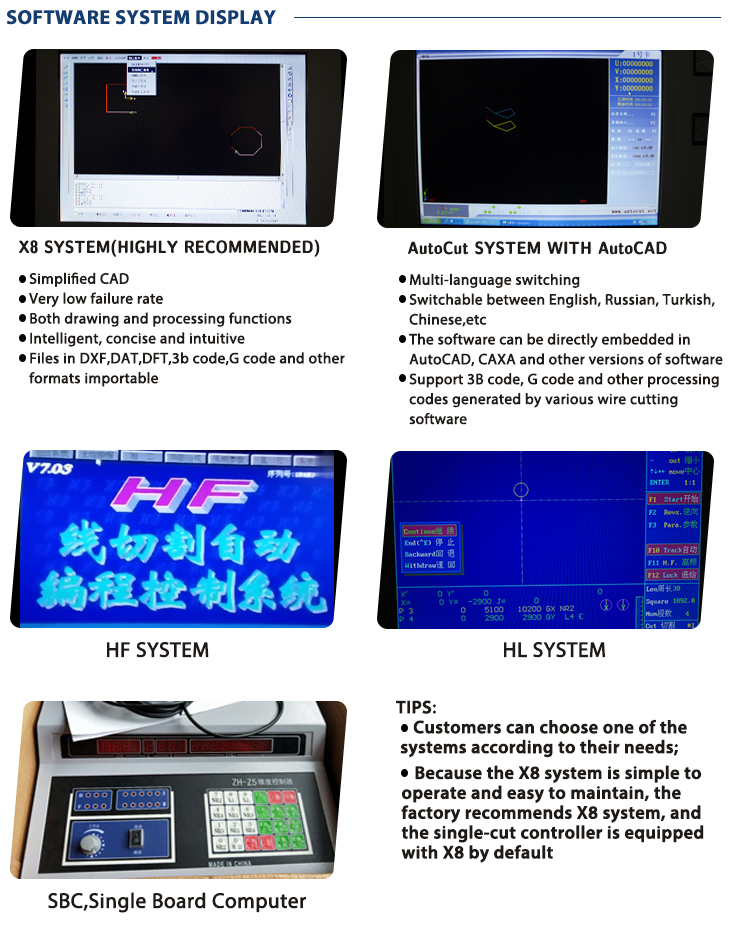

더구나 가장 최신판 X8 programming software 장착 가공형상 셋팅도 매우 편하고

가공 유지비도 대폭 절감됩니다

초정밀도가공조건이 10미크론이하도 허용될시 바로 딱입니다

물론 동선 와이어컷에 비해 가공정밀도/조도/가공속도/와이어 셋팅에 불편함도 있으나

기계가격 약 25% 선으로 장기간 유지비 고려시 매우 경제적 장비 가격임

더욱이 몰리브덴 와이어 컷팅기 사용처에서 실물 기계와 기능 확인가능 합니다

서울지역/창원지역 등

이제 와이컷 가공기구입 장비확보에 따르는 큰 자금부담없이

몰리브덴 와이어 가공기 구입으로 와이어 가공부담을 해결하시기 바랍니다

*시운전 포함 사후관리 완벽하게 진행됩니다

초정밀 와이어컷 가공10미크론이하라면

moly wire cutting 기 사용 유리

*PCB 교체비도 대폭 절감

Comparison between Moly-wire and Brass-wire Machines | ||

Compare Item | Moly-wire Cut machines | Brass-wire cut machines |

Cutting Wire | Moly wire | Brass wire |

Accuracy | around 8-12um( micrometer) | around 3-5um |

Roughness | around 0.8-1.2um | around 0.3-0.5um |

Max utting Speed | around 220-250MM2/MIN | around 240-350MM2/MIN |

Running cost | Moly-wire can be used for 3-5 days; The PCB board for Moly-wire cutting machine is around USD220/PC | Brass-wire is one time use; The PCB for Brass wire cut machine is around USD2200. |

The cost of the machine | 1/10 to 1/7 of brass-wire machines | 7-10 times that of moly-wire machines |

The way of thread wire | manual | automatic |

The way of coolant | only have flushing type | has Flushing and Submerge |

초정밀 와이어컷 가공10미크론이하라면 moly wire cutting 기 사용 유리

*PCB 교체비도 대폭 절감

Comparison between Moly-wire and Brass-wire Machines | ||

Compare Item | Moly-wire Cut machines | Brass-wire cut machines |

Cutting Wire | Moly wire | Brass wire |

Accuracy | around 8-12um( micrometer) | around 3-5um |

Roughness | around 0.8-1.2um | around 0.3-0.5um |

Max utting Speed | around 220-250MM2/MIN | around 240-350MM2/MIN |

Running cost | Moly-wire can be used for 3-5 days; The PCB board for Moly-wire cutting machine is around USD220/PC | Brass-wire is one time use; The PCB for Brass wire cut machine is around USD2200. |

The cost of the machine | 1/10 to 1/7 of brass-wire machines | 7-10 times that of moly-wire machines |

The way of thread wire | manual | automatic |

The way of coolant | only have flushing type | has Flushing and Submerge |

Comparison between Moly-wire and Brass-wire Machines | ||

Compare Item | Moly-wire Cut machines | Brass-wire cut machines |

Cutting Wire | Moly wire | Brass wire |

Accuracy | around 8-12um( micrometer) | around 3-5um |

Roughness | around 0.8-1.2um | around 0.3-0.5um |

Max utting Speed | around 220-250MM2/MIN | around 240-350MM2/MIN |

Running cost | Moly-wire can be used for 3-5 days; The PCB board for Moly-wire cutting machine is around USD220/PC | Brass-wire is one time use; The PCB for Brass wire cut machine is around USD2200. |

The cost of the machine | 1/10 to 1/7 of brass-wire machines | 7-10 times that of moly-wire machines |

The way of thread wire | manual | automatic |

The way of coolant | only have flushing type | has Flushing and Submerge |

1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional)

2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm)

3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut);

4.Molybdenum wire diameter:0.1-0.2mm;

5.Max. cutting speed≥120mm^2/min;

6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW;

7.Working fluid:Water-based emulsion.