중국 산 신품 기어 호빙기

문의 덕주코리아 010 2845 4417

문의 시 다양한 자료 제공합니다

중국산 각종 공작기계 취급 전문 -덕주코리아

다양한 공작기계 자료 문의 바랍니다

Send your message to this supplier

CNC High Speed Dry Cutting Gear Hobbing Machine

GHE-260CNC6 GHE-260CNC7

Machine Summary

The model GHE-260CNC6 high speed & dry cutting CNC gear hobbing machine is of 6 axes one with 4 axes coordinated control. The model GHE-260CNC7 high speed & dry cutting CNC gear hobbing machine is of 7 axes one with 4 axes coordinated control. They adopts dry cutting for the environmental protection and has the functions of chamfering and deburring. Based on the principle of generating method, and by electronic gearbox(EGB), these machines are designed to cut cylindrical spur & helical gears, dual & cluster gears, crowning or slightly tapered gears, splines, wormwheels, and sprochets etc. They are suited for the industries that produce the gears on a large scale production, such as automobile, motorcycle, textile machinery, crane machinery and lift, etc.

Performance and Feature

1. The model GHE-260CNC7 high speed & dry cutting CNC hobbing machine is of 7 axes with 4 axes coordinated control. Its CNC axes are:

- A-axis--hob head swivel motion;

- B-axis--hob spindle rotary motion;

- C-axis--worktable rotary motion;

- X-axis--radial feed motion;

- Y-axis--tangential feed motion;

- Z-axis--axial feed motion;

- U-axis--mechanical hand rotary motion;

- Each motion axis is driven independently by an AC servo motor.

2. Dry-cutting process for green environmental protection is adopted. Tooth chamfering and deburring functions are integrated in the machine.

3. Both hob spindle and work spindle transmission system are equipped with clearance eliminating and damp adjusting mechanisms to ensure their rigidity and accuracy.

4. Hardened steel guideways and linear recirculating roller guidance system are used for each linear motion part, imported pre-loaded precision ball screw pairs are used, imported super precision and high rigidity compound bearings are used for supporting the ball screws. Therefore, the machine has high rigidity and well suited for high speed and heavy-duty cutting. For cutting the workpiece with module about 5mm.

5. Equipped with internal and external fully-enclosed guards, perfect chip conveyor and dust collector.

6. This machine embodies the developing trend and design concept of manufacturing industry in environmental protection, automation, flexibility, high speed, high efficiency, and function combination.

7. It is suited for cutting cylindrical spur & helical gears, worm wheels, slightly tapered and crowning gears, splines and sprockets, etc.

Technical Parameters

| Specifications | Units | GHE- 260CNC6 | GHE- 260CNC7 |

| Max. workpiece dia. | mm | 260 | 260 |

| Max. module | mm | 6 | 6 |

| Max. axial travel | mm | 350 | 350 |

| No. of teeth | 4-1000 | 4-1000 | |

| Max. hob dimension(dia.*length) | mm | 160*230 | 160*230 |

| Max. chamfering cutter diameter | mm | 220 | |

| Spindle taper bore | ISO40 | ISO40 | |

| Worktable surface diameter | mm | 245 | 245 |

| Max. hob head swivel angle | deg | ±45 | ±45 |

| Center distance between hob and worktable | mm | 30-300 | 30-300 |

| Distance between hob axis and worktable surface | mm | 125-475 | 125-475 |

| Distance between tailstock center end face and worktable surface | mm | 335-785 | 460-760 |

| Max. hob tangential travel | mm | 180 | 180 |

| Max. spindle speed | rpm | 1500 | 1500 |

| Spindle speed of chamfering cutter | rpm | 18/75 | |

| Max. worktable speed | rpm | 100 | 100 |

| Radial rapid travel speed | mm/min | 3000 | 3000 |

| Tangential rapid travel speed | mm/min | 2000 | 2000 |

| Axial rapid travel | mm/min | 3000 | 3000 |

| Linear coordinate resolution of CNC axis | mm | 0.001 | 0.001 |

| Rotary coordinate resolution of CNC axes | deg. | 0.001 | 0.001 |

| Main motor power | kw | 22 | 22 |

| Total power | Kva | 50 | 55 |

| Main machine weight | kg | 15000 | 17000 |

| No. of cases | 2 cases in total | 2 cases in total |

Standard Attachments

- Φ40 hob arbor assembly

- Washer for hob arbor

- Fully-enclosed guards

- Dust collector

- Oil chiller for lubricant

- Cylinder for clamping workpiece

- Hand hold unit

- RS232 interface

- Machine data storage disc

- 10.4" color display

- Dual-hand operation system

- Tools for installation

- Tools for adjustment

- Chip conveyor

- Vibration isolating pads

- Auto. hob arbor clamping device

- Metered lubrication system

- Workstay

- Hydraulic system

- Lubricating system

- Electrical cabinet with air conditioner

- Spare parts for one years maintenance

- Interlock safety switch

- Multi-color tower light for indicating machine status

- Chip cart

Optional Attachments

- Auto. loading & unloading system

- Auto. workpiece storage system

- Deburring device

- Independent hob adjusting device

- Hob arbor

- Workpiece fixture

- Worktable positioning mechanism

- Separated workpiece counter

- Auto. door

- Software for 4 axes coordinated control(B, C, X and Z axes)

- Parameterized programming

- Man-machine conversation programming

- Machining wormwheel with tangential method

- Function of cutting cone root spline

Commercial Components

- Germany SIEMENS840D or Japan FANUC 31i CNC system

- Germany INA or Switzerland SCHNEEBERGER linear recirculating roller guidance system

- Taiwan HIWIN ball screw

- Germany spindle bearing and other key bearings

- Japan NACHI or Taiwan Conpass hydraulic component

- Gearmany sealing component

- Taiwan HABOR oil chillers for lubricant

CNC gear hobbing machine

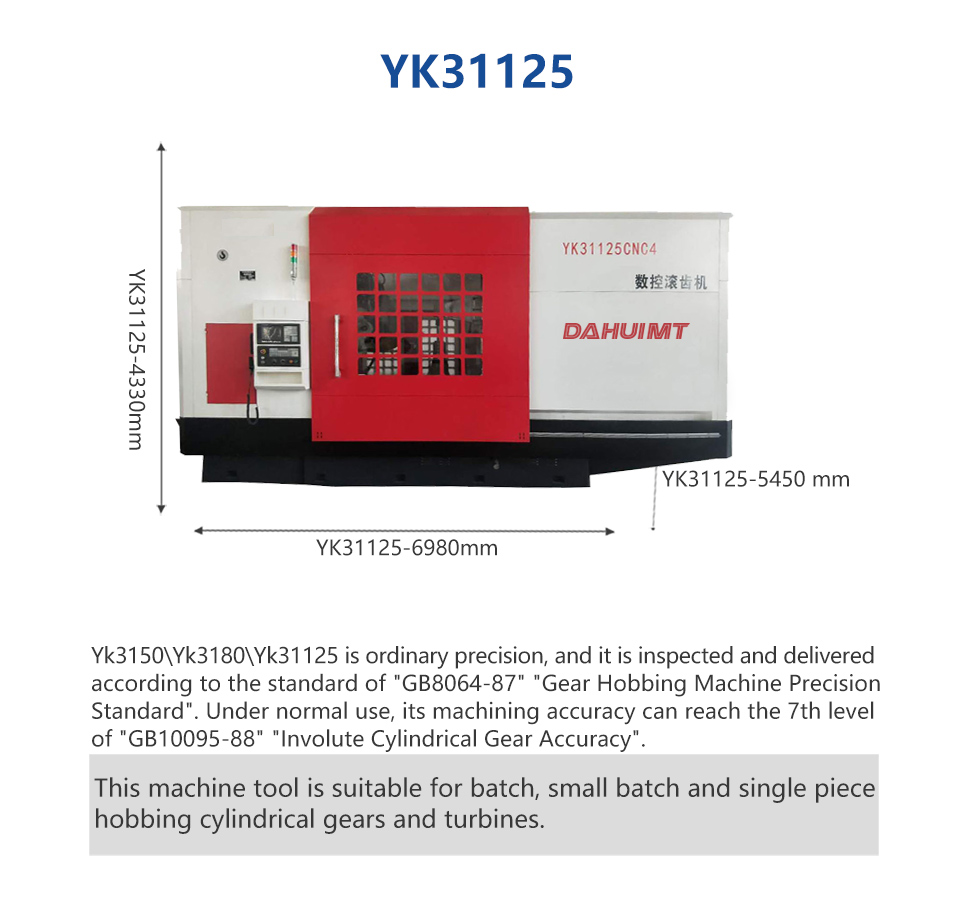

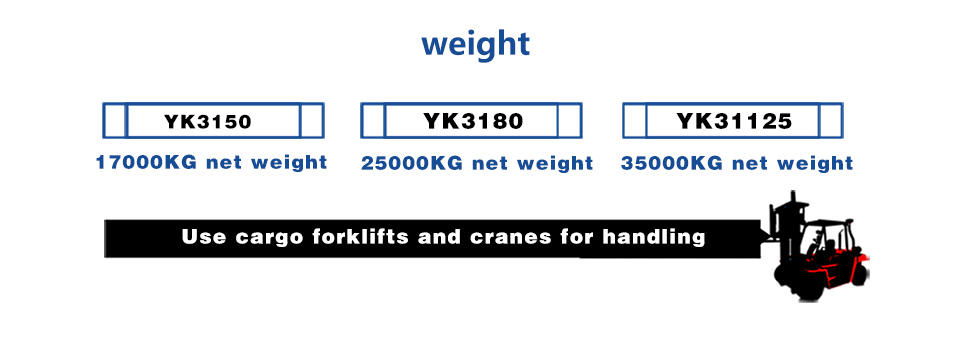

At present, our company's product models include gear hobbing machine series: YK3150E, YK3180H, YK31125ET, YK31315, YK3180CNC,YK3180CNC4, YK31125CNC, YK3650CNC4. It can also be designed and customized according to customer needs. The company has more than 20 years of professional manufacturing history and a strong technical team.

1.The machine tool adopts a vertical layout with a large column fixed on the bed and the worktable moves horizontally and

radially, with compact structure and beautiful appearance.

ball screw pair is selected to ensure the motion accuracy and positioning accuracy of the controlled axis.

Z-axial feed movement. Four linkages of B axis, C axis, X axis and Z axis.

guide rail pair and ball screw pair of the machine tool adopt an independent centralized quantitative lubrication system for

precise and quantitative lubrication. The lubrication interval can be adjusted. The system has a liquid level alarm and an oil

circuit block alarm.

1.bed

90--100 days for large-scale gear hobbing machine customization, depending on the user’s contribution to the description of the function to discuss the details.

Logistics transportation

After the equipment is commissioned in the factory, the whole machine is shipped, and the domestic standard logistics;international sea transportation, the transportation packaging is made of fumigation-free wooden boxes, please contact customerservice for special circumstances.

Please refer to the actual situation according to the following comparison chart.

Machine Parts

Name: Worktable

High precision worm worm gear pair, the realization of the workbench no clearance transmission, meet the accuracy requirement of the teeth.

Table adopts integral structure, good rigidity structure. Workbench structure stability, to better absorb, cutting force and transfer it directly to the base of the machine tool. Has a good damping effect of cutting force and strong rigidity.

Main Features

Name: CNC Controller

CNC control system; Mitsubishi CNC control system; Optional accessories for Fanuc or Siemens easy operating and reliable running.

Machine Parts

Name: Arbor

X, Y, Z feed drive adopts Siemens AC servo feed motor driver, ball screw drive, high precision ball screw bearing group.

Main Features

Name: COOLANT CHIP SYSTEM

Cooling machine adopts two sets of large flow, high head cooling pump, can be used independently, also can be used at the same time. Coolant recovery system is stable and reliable. Equipped with coolant, refrigeration equipment to keep machine tool thermal equilibrium. Equipped with oil mist collection device. Equipped with automatic chip removal unit, automatic separation of the chip side by side, including the scrap car.

DAESANG MACHINE DEZHOU KOREA CORP. TEL:82-2-2068-3312

M:010-2845-4417 E-MAIL :sksea99@daum.net

CHINA DEZHOU PRECION www.dzjc.com GRINDER www.sunnyfreeport.com

중국 공작기계 안내 -덕주코리아 문의 010 2845 4417

주요공작기계편 (metal cutting/chip making)

선반/밀링/연마기/드릴링/와이어 컷

판형가공기계 (metal forming/non-chip making)

프레스/절곡기/파이프 밴더등

지속적으로 판매가 확대되고 있는 주요 기계기종

1.선반 :초소형 선반/대주축경 선반/장축선반/대형선반

2.디프홀 가공기 : 보오링/드릴링기/SRB/호닝/BTA/GUNDRILL/복합가공기

3. 밀링기: 1.5호 소형밀링기 양두밀링

4. 연마기 : 칼날연마기/소형 연마기/평면연마기/가공 특수 연마기

5. 드릴링기 : 래디얼/엎라이트/탶가공기

6. 와이어 컷

7. 프레스 초소형 탁상용 /CS프레스

덕주코리아 취급전문 BEST5 소형기계/대형기계

-소형기계 : 1.5호 밀링기/ 칼날연마기/소형선반(대주축경)/레디얼/와이어 컷

-대형기계: 대형장축선반/디프홀기/양두밀링/원통연마기/수직선반(범용)

덕주코리아 주요 업무 써비스

-중국공작기계 수출입 업무/해외직구 컨설팅

* 중국산 대형기계 중국으로 수출판매 상담

* 중국산 신품/중고 매매 상담

* 중국산 공작기계 A/S 및 부품 조달

*각종 대형프로젝트 공장 공무복합시설

중국산/대만산 종합 견적 자료 제공

주요업체 홈페이지 참조후 문의요망

선반과 디프홀 가공기 (수직선반 포함) www.dzjc.com

밀링기/래디얼/더블컬럼 머시닝 센타 www.weida-mc.com

각종 연마기

*칼날 연마기 (평날/원형) www.bstsk.com

*원통 연마기 www.smtw.com

*로타리 연마기 www.lqhongxin.com

칼날연마기 특별 취급전문 문의 매우 유익한자료 제공됨

대만 연마기

평면연마기 www.sunnyfreeport.com

로타리연마기 www.grintimate.com

특수연마기 취급 (대만산/중국산)

스프링 기계 YHM www.wire-machine.com.tw

대만선반 KINWA www.kinwa-lathe.com

-------------------------------------------------

중국 판형기계 (METAL FORMING)취급전문 덕주코리아

C형 고속프레스 중국 최선도 기업 www.goanwin.com

절곡기/절단기 www.ysdcnc.com

중국 와이어 컷팅기 www.teruimachine.com

중국 목가공기 www.zicar.net

중국 사출기 HAITAI NINGBO www.haitai-machine.com

중국 판형 가공 ACCURL www.accurlcnc.com

중국 알류미늄 가공기 HAIJINNA www.win-doormachine.com

해외직구 관련 주요 컨설팅

기종별 최우수 선도업체/가장 무난한 기종 선정

사전에 미리 챙기는 기종별 소모품

사후관리 요구되는 문제 대비

직수입에 따르는 운송비 절감및 사전 대책 강구

(함께 수입하는 것으로 운송비 /통관비 절감 모색)

디프홀가공설비(선반포함) 복합전문 설비 상담

- 실린더 정밀 가공 복합설비등

선반 : 수평선반/수직선반/대주축경 선반

(디프홀 가공기 일체 포함:

보오링:PUSH&PULL/드릴링/호닝/SRB/BTA/GUNDRILL/

6AXIS/SPIRAL MILLING/WAVE CUTTING등 일체)

각 종 특수가공 전용기설비 문의 (복합기포함)

실린더라이너 황삭/정삭설비등 해양 시추설비 관련

디프홀 가공설비 내륙/해상 풍력에너지 관련 가공설비등

*가장 선반/디프홀기 관련 경험이 축적된 중국

덕주에서 가장 혁신적으로 기계 설계 /디자인하여 부담없는 가격에 공급

선반 집중 탐구

소형 선반

100만원 부터 800만원

180*300

210*400/700 * 38파이도 있음

250*500/750

280*550/610/815

320*600

330*550/750

360*750/1000

400*1000 가격대

800만/1000만/1250만/1500만/1750만/2000만

베드폭 200/250/300/350/400MM

주축경 38/40/52/58/80/100파이

모터 마력/기계중량/기타 스펙 변화

중국 소형선반

추천 기종

다기능선반 410*750 경량급 모델 450만원

정식규모 구조 선반

320*750 38파이 주축경 680만원

400*1000 경량급 750만원

400*1000 중급 1000만원

400*1000 기본 중량급 1500만원

400*1000 초우량급 1950만원

공작기계 기본설비 상담 전문

선반/밀링/연마기 염가구비 상담 전문

대형선반 디프홀 가공 설비상담전문

대형 밀링 가공설비/연마 설비 상담 전문

칼날연마기 취급전문

<공작기계 기종별 살펴보기>

중국 선반의 모든 것 덕주코리아 제공

수평선반/수직선반

1. 초소형 탁상선반

(동일가격으로 해외직구 상담 컨설팅 지원)

2. 소형선반/중형선반/대형선반

(가성비 높은 모델 선정 추천/부담없는 가격제공)

3. 대주축경 선반

(이왕이면 다홍치마 대주축경 선반 구득 생산성 제고)

4. 장축선반

(18 METER 선반 기공급)

5. 초 강력반

(중국 덕주선반 초강력반 세계시장 선도)

6. 디프홀 보링바/연마장치 장착선반

(선반추가 기능 보완 가공효율성제고)

7. 오방구 선반

부담없는 가격으로 신품 가격 제공

8. 대형 선반 척

9. 선반 옵션 추가 필요부품

10 . 덕주선반( 중국 선반) A/S 부품 공급

*** 수직선반도 전 세계시장 선도 합니다

밀링기의 모든 것 덕주코리아

1. 초소형 탁상밀링

2. 1.5호기 밀링

3. 양두밀링

4. 프레너 밀러

5. 각 종 특수 밀링기

연마기의 모든 것 -덕주코리아 제공

1.칼날연마기 취급전문

수동/반자동/자동

소형/중형/초대형

2. 평면연마기

대만 써니 연마기

중국 연마기 초소형 (미국 OEM) 탁상 연마기

중국 공구연마기 ( CUTTERMASTR 에어베아링)

중국 상해 원통연마기