선반의모든 것 원스톱 완전해결 문의 덕주코리아 010 2845 4417

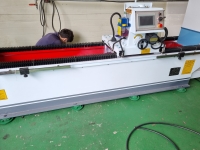

중국 대형선반 중고 ---> 중국 으로 역수출

중국 신품선반

국내/해외진출공장 중국 선반 공급 취급전문

초소형부터 초대형 까지

덕주코리아 주요취급기계 안내

1.소형기계

소형선반/소형밀링/소형 연마기(평면/원통/칼날/공구)/소형레디얼

소형선반 스윙 200-400* 가공길이 500mm- 1500mm

소형밀링 1.5호기/2호기

2. 주요 취급기계 홈페이지 참조

중국 덕주 선반/디프홀 가공기계 www.dzjc.com

중국 원통연마기 www.smtw.com

대만 평면연마기 www.sunnyfreeport.com* 대만 써니연마기 최고봉

대만 로타리 연마기 www.grintimate.com

중국 웨이다 밀링/레디얼 www.weida-mc.com

3.특수기계 간략안내

디프홀 가공 관련 모든 기종 취급전문

드릴링/보오링(PUSH/PULL TYPES)/SRB/BTA/호닝/건드릴/6축가공기

특히 복합기/실린더 가공 정밀가공설비등 가공 전문설비

양두밀링/밀링.연마복합가공기

칼날연마기(평날 원형)

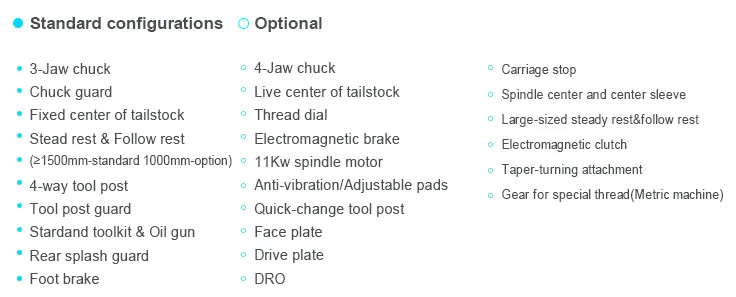

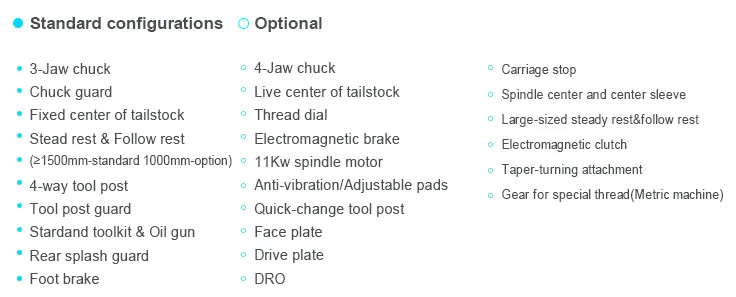

Product Description | |||

| Bench Lathe CZ1440G/1 | |||

| Supersonic frequency hardened bed ways | |||

| Precision roller bearing for spindle | |||

| High quality steel, ground and hardened gear inside headstock | |||

| Easy and fast operating gearbox | |||

| Enough strong power motor | |||

| ASA D4 camlock spindle nose | |||

| Various threads cutting functions available | |||

| BENCH ALTHE Model | CZ1440G/1 | ||

| Main data | Swing over bed | mm | φ 355 |

| Swing over carriage | mm | φ 220 | |

| Swing over gap | mm | φ 500 | |

| Width of bed-way | mm | 186 | |

| Distance between centers | mm | 1000 | |

| Spindle | Taper of spindle | M. T. 5 | |

| Spindle diameter | mm | φ 38 | |

| Step of spindle | 8 | ||

| Range of spindle | rpm | 70~2000 | |

| Head | D1-4 | ||

| Thread and feed system | Metric thread | 23kinds (0.25~11mm) | |

| Inch thread | 40kinds(4~112T. P. I) | ||

| Longitudinal feeds | mm/r | 0.091~2.553 (0.0036” ~0.1005” ) | |

| Cross feeds | mm/r | 0.025~0.69 (0.0012” ~0.0345” ) | |

| Main lead screw | Diameter of lead screw | mm | φ 22(7/8” ) |

| Pitch of lead screw | 3mm or 8T. P. I | ||

| Saddle and carriage | Saddle travel | mm | 1000 |

| Cross travel | mm | 170 | |

| Compound travel | mm | 74 | |

| Tailstock | Barrel travel | mm | 95 |

| Barrel diameter | mm | φ 32 | |

| Taper of center | mm | M. T. 3 | |

| Power | Motor power | Kw | 1.5(2HP) |

| Motor for coolant system’ s power | Kw | 0.04(0.055HP) | |

| Shipment data | Machine(L× W× H) | mm | 1920× 750× 760 |

| Stand (left) (L× W× H) | mm | 440× 410× 700 | |

| Stand(right) (L× W× H) | mm | 370× 410× 700 | |

| Machine | Kg | 505/565 | |

| Stand | Kg | 70/75 | |

| Loading qauntity/20" container | pcs | 22 | |

Including the following acces.

중국공작기계 집중 파악 안내 -덕주코리아 제공 추가문의 010 2845 4417

선반 : 매우 가성비가 높으며 이제 범용선반의 경우 전세계 OEM 공급 지배

밀링: 1.5호기 거의 장악/ 양두밀링비롯 대형밀링도 상당한 선까지 시장지배

연마기: 아직 조금 정밀도에서 부족이나 특수 연마기는 미국OEM경험/독일기술 접목으로 일부 기종 상당수준

디프홀기기종: 가성비에서 추종불허(가격 부담없고 성능거의 세계최고수준)

레디얼드릴링기/엎라이트/각종 대형 범용 보오링기/수직선반/세이퍼 등 공무정비시설 구비에 최적합

심층 도움자료

<선반과디프홀기 >www.dzjc.com 참조후 문의 덕주코리아 010 2845 4417

선반 : 수평선반/수직선반/대주축경 선반

(디프홀 가공기 일체 포함: 보오링:PUSH&PULL/드릴링/호닝/SRB/BTA/GUNDRILL/6AXIS/SPIRAL MILLING/WAVE CUTTING등 일체)

각 종 특수가공 전용기설비 문의 (복합기포함)

실린더라이너 황삭/정삭설비등 해양 시추설비 관련 디프홀 가공설비 내륙/해상 풍력에너지 관련 가공설비등

*가장 선반/디프홀기 관련 경험이 축적된 중국 덕주에서 가장 혁신적으로 기계 설계 /디자인하여 부담없는 가격에 공급합니다

선반과 디프홀기 관련 모든 문의 척척박사 덕주코리아와 협의 바랍니다

<밀링과레디얼 (프레너 밀러/양두밀링 포함)>www.weida-mc.com 문의 덕주코리아

부담없는 가격 신속정확한 공급/사후관리 지속적 관리에 역점을 두고 있읍니다

*** 1.5호기 밀링 센타운영(중국 레디얼기포함)

1.5호기 밀링에관한 원스톱 총괄써비스

1. 신품구입 (국내용/해외공장용)

2. 중고 교체 신품구입상담

3. 기존 사용 1.5호기 밀링 수정보완 처리 상담

4. 각종 특수 부품 별도 구입 상담

5. 1.5호기 밀링 부품 조달 (A/S용도)

중국 공장에 거의 상시 재고 보유 상태 유지 합니다

일반 납기 소요기일 약 15일 내 처리합니다

부담없는 가격으로 공급합니다

1.5호기 밀링에 관한 한 종합써비스 센타로 더욱 더 나은 써비스가

이루어지도록 하고자 합니다

아울러

초소형부터 초대형 밀링기전반 상담문의 바랍니다

<연마기 >

중국/대만 을 통합 거래를 통해 귀사에 적합한 기종 모델 엄선하여 추천합니다

<평면연마기>

대만 최고봉 써니 연마기 www.sunnyfreeport.com

중국 최고봉 위해 연마기 www.whfengrun.cn

<칼날연마기> 중국 www.bstsk.com

<원통연마기> 중국 www.smtw.com

<로타리 연마기>대만 www.grintimate.com(소형원통포함)

공작기계/산업기계 종합설비 문의 바랍니다

국내공장용/해외공장용/종합공무설비등(중국산/대만산 종합 비교검토 자료 제공 가능)

주요 공급업체 홈페이지 참조

중국 덕주 기상창 www.dzjc.com 참조 (주요 생산 기종:선반과 디프홀기)

중국 웨이다 기상창 www.weida-mc.com(주요 생산기종: 밀링과 레디얼)

대주축경선반 www.yishuilathe.com

소형 탁상선반 www.jinxingjichuang.com

양두밀링 www.singfuchen.cn

평면연마기 www.yd-tieju.net www.whfengrun.cn www.sunnyfreeport.com

원통연마기 www.smtw.com

칼날연마기 www.bstsk.com

공구연마기 www.hr-machinetools.com

각종 디프홀 관련기기와 각종 연마기 관련 문의

각별히 상세정보 신속정확하게 제공합니다

Product Description | |||

| Bench Lathe CZ1440G/1 | |||

| Supersonic frequency hardened bed ways | |||

| Precision roller bearing for spindle | |||

| High quality steel, ground and hardened gear inside headstock | |||

| Easy and fast operating gearbox | |||

| Enough strong power motor | |||

| ASA D4 camlock spindle nose | |||

| Various threads cutting functions available | |||

| BENCH ALTHE Model | CZ1440G/1 | ||

| Main data | Swing over bed | mm | φ 355 |

| Swing over carriage | mm | φ 220 | |

| Swing over gap | mm | φ 500 | |

| Width of bed-way | mm | 186 | |

| Distance between centers | mm | 1000 | |

| Spindle | Taper of spindle | M. T. 5 | |

| Spindle diameter | mm | φ 38 | |

| Step of spindle | 8 | ||

| Range of spindle | rpm | 70~2000 | |

| Head | D1-4 | ||

| Thread and feed system | Metric thread | 23kinds (0.25~11mm) | |

| Inch thread | 40kinds(4~112T. P. I) | ||

| Longitudinal feeds | mm/r | 0.091~2.553 (0.0036” ~0.1005” ) | |

| Cross feeds | mm/r | 0.025~0.69 (0.0012” ~0.0345” ) | |

| Main lead screw | Diameter of lead screw | mm | φ 22(7/8” ) |

| Pitch of lead screw | 3mm or 8T. P. I | ||

| Saddle and carriage | Saddle travel | mm | 1000 |

| Cross travel | mm | 170 | |

| Compound travel | mm | 74 | |

| Tailstock | Barrel travel | mm | 95 |

| Barrel diameter | mm | φ 32 | |

| Taper of center | mm | M. T. 3 | |

| Power | Motor power | Kw | 1.5(2HP) |

| Motor for coolant system’ s power | Kw | 0.04(0.055HP) | |

| Shipment data | Machine(L× W× H) | mm | 1920× 750× 760 |

| Stand (left) (L× W× H) | mm | 440× 410× 700 | |

| Stand(right) (L× W× H) | mm | 370× 410× 700 | |

| Machine | Kg | 505/565 | |

| Stand | Kg | 70/75 | |

| Loading qauntity/20" container | pcs | 22 | |

Including the following acces.

1.M Hanna high strength cast iron, internal honeycomb rib structure, high rigidity, long service life.

2.Spindle adopts imported from Japan King combination diamond. After the quenching and tempering and frequency processing, after

fine grinding with 4 imported bearings (other manufacturers spindle 3 bearing), ensure high quality and high precision.

3.Three shaft screw fine grinding with advanced phosphor bronze nut, durable.

4.Horizontal milling with 4 gear shaft speed (other manufacturers for the 2 gear shaft), a wide range of variable speed, torque.

Application:

The milling machine is a kind of universal light duty metal cutting machine,

Has two functions of vertical and horizontal milling, Milling medium, small parts of the plane, inclined plane, groove and spline etc..

1. Robust construction and heavy duty design.

2. The machine body is made of Meehanite cast iron

3. The milling head is made of SCM-21.Imported from Taiwan.

4. The milling head can swing 90° right and left side,45° front and back side.

5. The working table and guide rail are heating treated and precision grinding, ensure the machine has high rigidity and high precision

6. DRO and dividing head are for option.

|

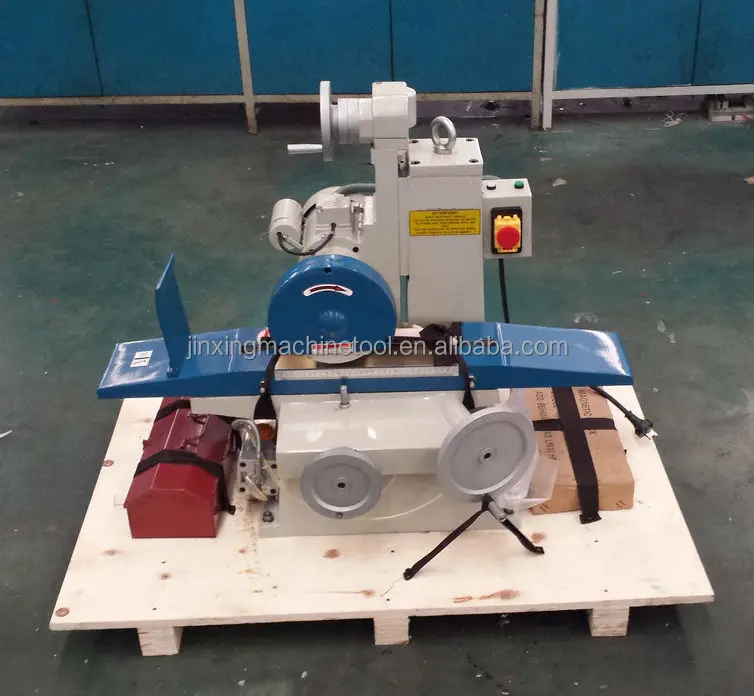

각종 소형연마기

덕주코리아 취급하는 소형 연마기

1.칼날연마기

2.평면연마기

3.공구연마기

기타 각종 연마기 문의 시 상세 정밀자료 바로바로 제공합니다

문의 덕주코리아 010 2845 4417

문의시 귀사 명함(이메일주소 포함) 제공 바랍니다

1.칼날연마기 모델 MFD400manual knife grinder

Specification

1 this is a manual model. You need to push the grinding head moveletf and right

2 the down feed system is manual ,working precision is 0.05mm/wheel

3 the working table use clamping table. It used for planer blade and crusher blade.

Model | MFD400 | Motor speed | 2800rpm |

Max sharpening length | 410mm | Motor power | 0.5kw |

Guide length | 600mm | Weight | 45kg |

Size | 740x400x640mm | Stone size | 125x32mm |

2. 평면연마기 MJ7115

INTRODUCTION:

surface grinder 6"*12" surface grinder is designed to grind various horizontal and vertical surfaces of the workpieces by the periphery and end faces of the grinding wheel respectively. It can also grind contoured workpieces with shaped wheel or craftsmanship apparatus. With small dimensions, light wight, smoothly safe operation and convenient maintenance, etc., it can be used in small enterprises, repairing shops, household industry, lab, teaching demonstrations, etc.

surface grinder 6"*12" FEATURES:

1.Integrated grinding head of high quality, high rigidity and accuracy,

2. small size and light weight, easy operation and maintenance,

3. centralized lubrication for oil pump

STANDARD CONFIGURATION

grinding wheel, grinding wheel adaptor,grinding wheel dresser, pad irons, tools, Rolling Guideetc

SPECIAL CONFIGURATION

stand, permanent magnetic chuck, precision flat vise

| SPECIFICATIONS | Metric | Inch |

| Longitudinal stroke | 340mm | 14 |

| Lateral stroke | 170mm | 7 |

| Grinding height | 210mm | 8 |

| Area of table | 152mm×304mm | 6×12 |

| Width of T-slot | 1-12mm | 1-0.47 |

| Cross feed per graduation | 0.02mm | 0.001 |

| Cross feed per round | 2.54mm | 0.1 |

| Vertical feeds per graduation | 0.025mm | 0.001 |

| Vertical feed per round | 1.25mm | 0.05 |

| Roughness | 1.6μm | |

| Grinding wheel | 180mm×32mm×13mm | |

| Power of motor | 0.55kw | |

| N. W. / G.W.of machine | 210/258kg | |

| N. W. / G.W.of stand | 30/54kg | |

| Overall dimension of machineL×W×H | 930×780×730mm | |

| Case dimension of machineL×W×H | 930×780×1480mm | |

| Case dimension of standL×W×H | 720×550×550mm | |

technical parameter:

End mill capacity (dia. Of shank x dia. Of edge x length) | 50 x 225 x 250mm, 2" x 9" x 10" |

Swing over table | 245mm, 9-3/4" |

Longitudinal travel (X axis) | 150mm, 6" |

Cross travel of table (Y Axis) | 75mm, 3" |

Max. Wheel: | 125 x 50 x 32mm, 5" x 2" x 1-1/4" |

Tilt adjustment for wheelhead | 35° -10° |

Air bearing swivel | 360° |

Air bearing stroke | 250mm, 10" |

Table infeed graduation | 0.02mm, 0.001 |

Air bearing graduation | 6.3MPa |

Pipe joint diameter | Z/4" 1 |

Collet fit for spindle | 5C |

Parallelism between two tables | 0.01/100mm, 0.01/100 |

Parallelism of sleeve center line to worktable | 0.01/100 |

Motor speed: 2, 800rpm | 3, 450/2, 580rpm |

Voltage | 230V 110V/1 phase |

Power | 0.25kW 1/3HP |

Frequency | 50Hz |

Max. Stroke of air bearing sleeve: 9"

Collect for work table: 5C

T-shaped slot width for table: 12.7mm

Air consumption: >0.63Mpa

Tracheal joints: 1/4"

Turning angle: 360degree

Parallelism of workhole center line to abse surface: 0.015mm

Radius run out of workhole center line(60mm for hole): 0.015mm

중국 공작기계 사후관리

중국공작기계 본격 수입시작된 1990년부터 30년 세월 경과

대형선반 덕주/심양/안양

중형선반 심양/대련

소형선반 마작선반

원통연마기 상해

평면연마기 항주/위해

보오링기/디프홀 드릴링기/레디얼 기/수직선반등

수많은 공작기계가 수입공급되었읍니다

덕주코리아는 상기 기계관련 A/S 부품 조달및 사후관리를 수행합니다

(실비로 처리수행합니다 많은 문의 바랍니다)

직수입 구매 주요 취급공작기계

1.주요 대형기계

중국 덕주선반과 디프홀기 www.dzjc.com

중국 웨이다 레디얼기와 밀링기 www.weida-mc.com

중국 몬 레이져가공기 www.mornlaser.com

2. 주요 특수기계

각종 연마기: 소형원통/펀치핀연마기/칼날연마기(원형/평날)/공구연마기/볼연마기등

각종 밀링기: 각치기밀링/양두밀링/문형밀링

3. 전문화 기종 디프홀가공기/공구

디프홀 드릴링/보오링/호닝/ BTA/SRB/GUNDRILL 6축가공기/SPIRAL MILLING기및

관련 가공 각종 툴 염가공급

4. WORKHOLDING및 정반 장비류 염가실비 제공 합니다

선반 척 대형/마그네틱척 대형/정반 대형(기계조립용/용접용등)

5. 전용기 제작문의및 전용기 제작용도 구조물기계몸체 조달 문의 바랍니다

덕주코리아 주요업무

1. 소요 기계 업체선정 및 추천 /적합모델/ 수입 경비절감 연구 등 컨설팅 제공

2. 각 기종별 모델별 특징및 기능을 상세히 제공 구매시 최적합 상태 도입지원

3. 예비부품/ 사후관리 고려 미리 확보에도 세심한 배려 제공

4. 여러 공급업체 성격및 장단점 고려 올바른 공급자 선정에 도움

디프홀 가공기 취급 전문 많은 문의 바랍니다

Hot sale CNC deep hole gun drilling machine

ZKB2102 is CNC Deephole drilling machine suited for drilling 3-D or 2-D hole system. It is adopting chip moved outer, with high efficiency, high accuracy , drill small-holes by "gun-drilling "method. It can instead of drilling,counting,reaming by one drilling process obtain sourcing accuracy. Bord accuracy is IT7-IT10, roughness Ra3.2-0.04µm, linearity<=0.05mm in 100mm length. It is used widely in plastic and rubber industry, hydraulic mechanism, automobile and tractor, generator and aviation industry for machining deephole porforation; such as cooling hole, elecheating hole, valve distributor, pump steering sharft, spindleheat-exchanger, plate, etc.

main parameters:

![]()

칼날연마기 참조바랍니다

중국 신품 분쇄기 칼날 연마기 상세안내

1. 초소형 탁상형 수동 칼날연마기 *작업대 수동이송형

2. 초소형 탁상형 수동 칼날연마기 *연마석 스핀들헤드 이송(레일)형

3. 스텐드 레일이송형 완전수동형

4. 스텐드 좌우 자동 이송형

5. 좌우이송 자동 상하 조절자동

1. 모델명 CBG206

| Model | WM 206 |

| Max. sharpening length | 650 mm |

| Max. sharpening width | 50 mm |

| Max. sharpening thickness | 5 mm |

| Angle of grinding blade | 37-42 degree |

| Disc mold | 100*20/32*50 mm |

| Power | 550 w |

| Voltage | 220v 50hz |

| Weight | 25 kgs |

| Dimension | 550*290*380 mm 700*140*200 mm |

The structure of small crusher knife-grinder planer blade knife sharpener

Main Feature of planer blade knife sharpener

1. The small crusher knife-grinder uses an export standard motor.

2. All cast iron body, more stable in use.

3. The blade sharpener uses a precision calibrated press guide.

4. The knife-grinder uses a white corundum grinding wheel.

Commissioning and operating procedures

This planer blade sharpener is suitable for grinding straight and planer knives.

1. During the knife sharpener's operation, the grinding wheel and the sliding table are adjusted to a certain small angle, so that the front edge of the grinding wheel is in contact with the blade to ensure the grinding quality of the blade.

2. The adjustment of the amount of the knife can be realized by shaking the hand wheel and moving the sliding table seat back and forth.

3. The adjustment of the sharpening angle can be realized by rotating the adjusting wire and adjusting the sliding table.

4. The knife has a protruding amount and can be adjusted with a top wire top knife.

5. After adjusting the above parameters during the sharpening, the blade to be ground is fixed on the tool holder by the pressing wire through the pressure plate, and the grinding operation can be performed by pushing the tool holder left and right

2. CBG 400 manual knife grinder

Specification

1 this is a manual model. You need to push the grinding head moveletf and right

2 the down feed system is manual ,working precision is 0.05mm/wheel

3 the working table use clamping table. It used for planer blade and crusher blade.

Model | MFD400 | Motor speed | 2800rpm |

Max sharpening length | 410mm | Motor power | 0.5kw |

Guide length | 600mm | Weight | 45kg |

Size | 740x400x640mm | Stone size | 125x32mm |

<레디얼기 >

기본형 40*1300

More details of our hydraulic radial drilling machine Z3040*13/1:

SEMI HYDRAULIC RADIAL 40*1300

Specifications | Z3040×13/1 |

Max. Drilling Dia. | 40 mm |

Distance from spindle nose to table surface | 260-1300 mm |

Headstock level migration distance | 900 mm |

Distance from spindle end to working table end | 360-1090 mm |

Lifting height of rocker arm | 720 mm |

The lifting speed of rocker arm | 1.32 m/mm |

Rocker rotary angle | ±180° |

Spindle taper | MT4 |

Spindle speed range | 32-1220 r.p.m |

Spindle speed step | 12 |

Spindle feeding range | 0.1-0.25 r.p.m |

Spindle feeding step | 3 |

Spindle travel | 280 mm |

Max. Torque of main spindle | 200 kg/m |

Max. Resistance of main spindle | 10000N |

Main motor power | 2.2 kw |

Weight | 1600 kg |

Overall dimension | 1800×810×2300 mm |

소중형 레디얼 스펙

Main Technical data | unit | Z3050X16 | Z3040x13 | Z3040X12 | 3032×10/1 | Z3032X10 |

Max Drilling capacity | mm | 50 | 40 | 40 | 35 | 32 |

Distance spindle nose to working surface of base | mm | 260-1150 | 260-1050 | 260-1100 | 140-1100 | 220-980 |

Distance spindle axis to column generating line | mm | 350-1600/1300 | 360-1100 | 360-1300 | 360-1000 | 260-1000 |

Spindle travel | mm | 220/280 | 220/280 | 220/280 | 200 | 120 |

Spindle taper | 5 | 4 | 4 | 4 | 4 | |

Spindle speeds range | R/min | 78-1100 | 34-1280 | 28-1200 | 75-1220 | 108-1000 |

Spindle speeds series | 6 | 6 | 12 | 6 | 6 | |

Range of Spindle feeds | Mm/r | 0.04-3.2 | 0.10-0.25 | 0.10-0.25 | 0.10,0.16,0.25 | |

Spindle feeds | 6 | 3 | 6 | 3 | ||

Rocker angle | ° | 360 | 360 | 360 | 360 | 360 |

Power of Main motor | kw | 4 | 3 | 3 | 2.2 | 1.5-2.2 |

Lift motor power | 1.5 | 1.1 | 1.1 | 1.5 | 0.75 | |

Machine weight | kg | 2300 | 1500 | 1500 | 1100/1200 | 800 |

Overall Size | mm | 2300x1060x2800 | 1600x705x2200 | 1600x700x2050 | 1500x705x2050 | 1235x600x1780 |

Feature:

1. Frequency conversion transducer spindle stepless digital readout for the display of speed

2 Strength spindle, with limiting protection or limiting position

3. Electrical box and coolant button is on the fight of spindle box

4. Hydraulic pressure clamp; interlock of rocker arm clamping and up down movement; clamping of spindle and spindle box could be simultaneous or separated

5.Trochoid thin oil lubrication

6.With safety protection device;

7.At the bottom of lead screw and guide surface can be add protection device;

8.Importable electrical components with CE,CSA,UL standard

9.Electric box control by PIC

10.Length worktable ,supply inclined worktable and quick change colt as optional accessories

Z6016 (과거 5016 모델 한칫수위 특수모델)

Specification:

Specification | ZB3060x16 |

Max. drilling diameter(on 45 steel) | Φ62 |

Max. drilling diameter(on HT200 cast iron) | Φ72 |

Max. tapping diameter(on Medium-carbon steel) | M46 |

Max. tapping diameter (on cast iron) | M52 |

Max. distance from spindle to generating line of column | 350-1600 |

Distance of horizontal movement for spindle box(manual) | 1250 |

Max. distance between spindle end to the worktable surface of the base | 350-1250 |

Max. travel of the spindle | 315 |

Spindle taper bore | MT.5 |

Spindle speed steps | Stepless |

Spindle speed range (r/min) | 38-275; |

Spindle feed steps | 8 |

Spindle feed range (mm/r) | 0.06-1.00 |

Speed of rocker arm up and down movement (m/min) | 1.2 |

Rotation angle of rocker arm (degree) | ±180 |

Distance of spindle movement for calibrated dial each revolution (mm) | 122 |

Power of main motor (transducer motor )(KW) | 4 |

Power of motor for rocker arm up and down movement (KW) | 1.5 |

Power of oil pump motor for spindle box, column and rocker arm clamping | 0.75 |

Weight of machine (without worktakbe) (Kg) | 3800 |

Machine dimension (LxWxH) (mm) | 2490x1000x2598 |

Standard accessory:

- Key type drill chuck;

-Connection bar for drill chuck;

-Shaft sleeve for taper shank tool;

-Wedge for taper shank tool.

-Optional accessory:

-Rotation worktable;

-Quick change collet

Optional accessory:

-Rotary table

-Quick change collet

63*2000