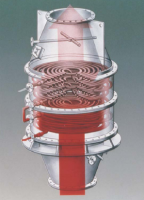

The Clayton Waste Heat Recovery System can be used to

generate steam or high temperature hot water. Typical combinations

of an exhaust gas or waste heat unit with a direct fired steam

generator are shown on page 5. A principal feature of the Clayton

Waste Heat Recovery System is its unique coil design. The

coil tube is wound in a spiral pattern with closely controlled spacing

between turns. This provides the desired area to control the

velocities of the boiler gases. This highly efficient heating surface

arrangement minimizes size and weight requirements.

The Clayton Exhaust Gas Boiler (EGB) is primarily used in

conjunction with a Prime Mover, such as a Turbine or Internal

Combustion Engine (100 kW to 15 mW), as part of a Distributed

Generation installation producing electricity or in marine/shipboard

applications. The typical Clayton EGB is constructed of

individual coil modules, with each module containing spirally

wound layers. The number of modules used depends upon the

exhaust gas flows, allowable back pressure and on the boiler

heat output requirements in steam or hot water.

The Clayton EGB module is available in various sizes and

configurations to meet individual requirements.

Clayton EGB modules can operate at temperatures up to

1,200°F (650 °C) and can run dry (without circulating water in the

tubes) at temperatures up to 840°F (450°C).

Once assembled with the appropriate coil modules, the

completed Clayton EGB includes inlet and outlet cones that permit

vertical or horizontal units with exhaust gas flows in any direction

For exhaust temperatures over 1,200°F

(650°C), the Clayton Waste Heat Steam Generator

(WHSG) is applied. The Clayton WHSG is primarily

used on incinerators, furnaces and thermal oxidizers

with exhaust temperatures up to 3,500°F (1,925°C).

The Clayton WHSG is designed much like the standard

Clayton direct-fired Steam Generator with water-

walls and air-cooled shells. Inlet and outlet casing

and connection pieces complete the unit for installation

in the client’s ductwork.

Another unique feature of both the Clayton EGB

and WHSG is the Clayton designed and manufactured

main feedwater positive displacement diaphragm pump.

The pump requires minimum maintenance since there are

no packings or mechanical seals to leak or require replacement.

Pistons are not exposed to feedwater being pumped

but run on lubrication oil so wear and tear due to the presence

of grit is eliminated.

As with the standard Clayton Steam Generator, all

the ancillary components such as the separator/steam

drum, feedwater tank, softeners, blowdown tank and

chemical pumps can be packaged on a common skid. All

piping and electrical work is completed by Clayton.